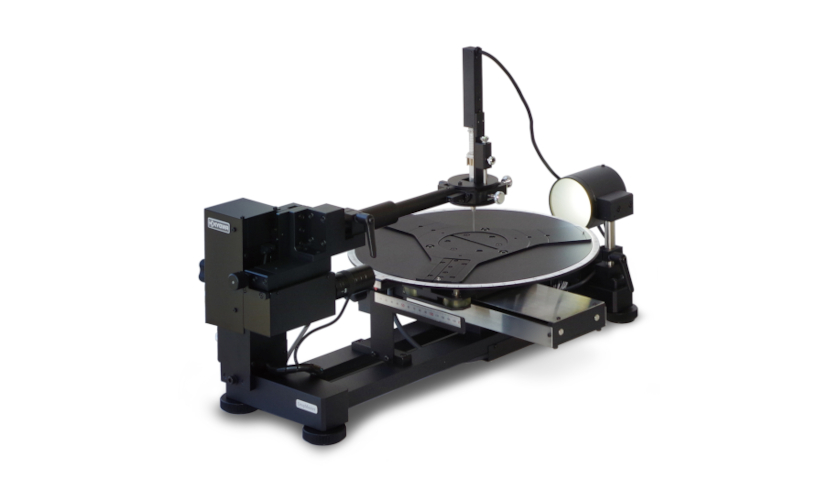

FPD-CP11

Device for large panels and wafers

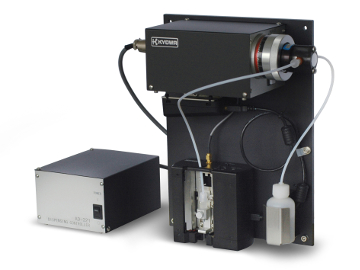

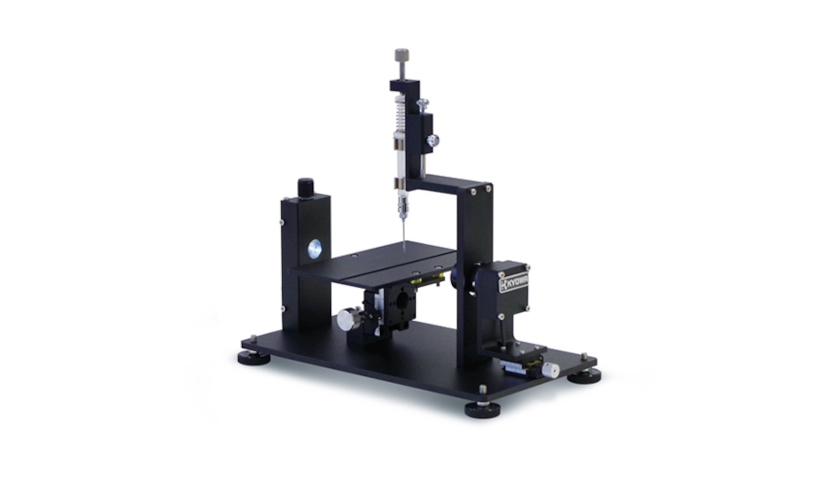

The FPD-CP11 system consists of the main measuring head, a metering pump with a 50mL capacity liquid container, and a control box, and it has been developed for non-contact measurements of contact angles on flat panel displays such as LCD, LED, OLED, and silicon wafer. It has been designed to be attached to metrology systems that combine several different measuring devices in one system. The communication and data transmission between this host system and our FPD-CP11 is achieved via an RS-232C serial port connection.

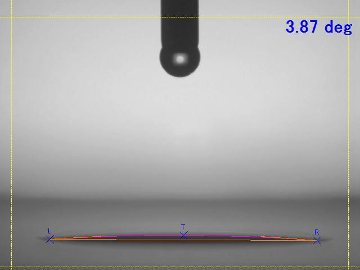

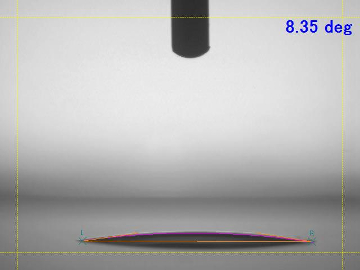

The system is specially designed to observe droplets with a lateral image capturing system and the optical system is set at a slight angle, making it possible to measure contact angles without having contact with the panel's delicate surfaces. Thanks to this lateral image capturing system, the FPD-CP11 is not limited to only 90º, such as top-view measuring systems, but instead, it delivers high-accuracy and reliable measurements in a range from about 3 to 175º.

- Single-click automatic measurements, to be operated from a host system

- Precise and reliable measurement of contact angles from about 3 to 175 degrees

- Time-dependent measurements by image capture up to 30 fps

- Metering pump, incl. a 50mL liquid container, allowing 50,000 1μl droplets with one prepared liquid container

- Droplet calibration standard for standard view, bearing one full circle for calibration and three droplet silhouettes of 5º, 60º, and 108º for periodic inspection of measurement accuracy

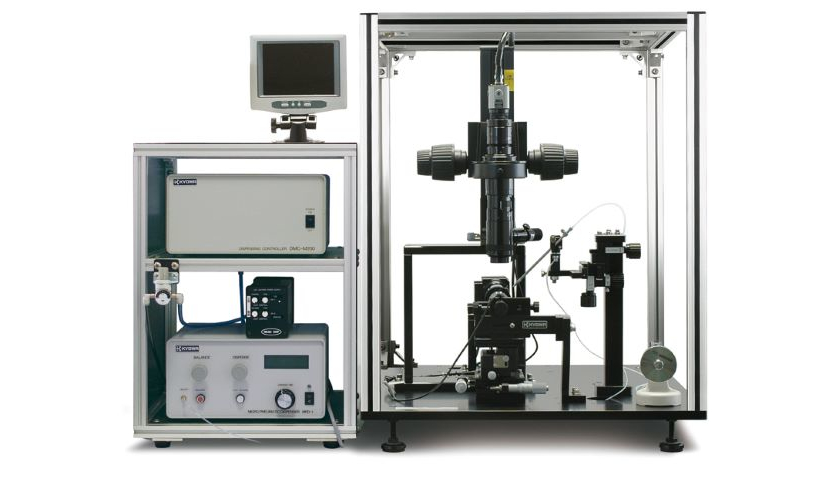

- No options are available for the FPD-CP11, but customized solutions are possible to adapt the FPD-CP11 to existing metrology systems

- Contact angle measurements to determine the surface cleanliness of flat panel displays such as LCD, LED, OLED, and silicon wafer

| FPD-CP11 | |

| Camera system | USB2.0 CMOS camera: 30fps at 640x480 pixels |

| Optical system |

focus: fixed focus with fixed focal length field of view: 6.3x4.7mm ±5% |

| Measuring methods | contact angle: sessile drop (static) |

| Analysis methods | θ/2, tangent, curve fitting (ellipse, circle) |

| Measuring range | 3 to 175° |

| Resolution | 0.1° |

| Accuracy1) | 0.5° |

| Maximum sample surface area and height (WxDxH) | no limitations |

| Dispenser operation: Droplet generation Droplet deposition Droplet resolution |

metering pump, incl. a 50mL liquid container automatic automatic 0.1μl |

| Dimensions (WxDxH) of: Main instrument Control box |

220x111x305mm 61x75x43mm |

| Approximately weight of: Main instrument Control box |

4.0kg 1.5kg |

| Electric power of: Main instrument Control box USB extension cable |

USB bus power, DC5V, max. 2W AC100-240V, 50/60 Hz, 13W 37VA AC100-240V, 50/60 Hz, max. 24W 24VA 1A |

| Operating environment |

temperature: +10 to +35℃, humidity: 30-80%RH (non-condensing) positioned away from sources of electrical noise and vibration |

1) Accuracy is the repeatability in terms of standard deviation based on the manufacturer’s calibration standard