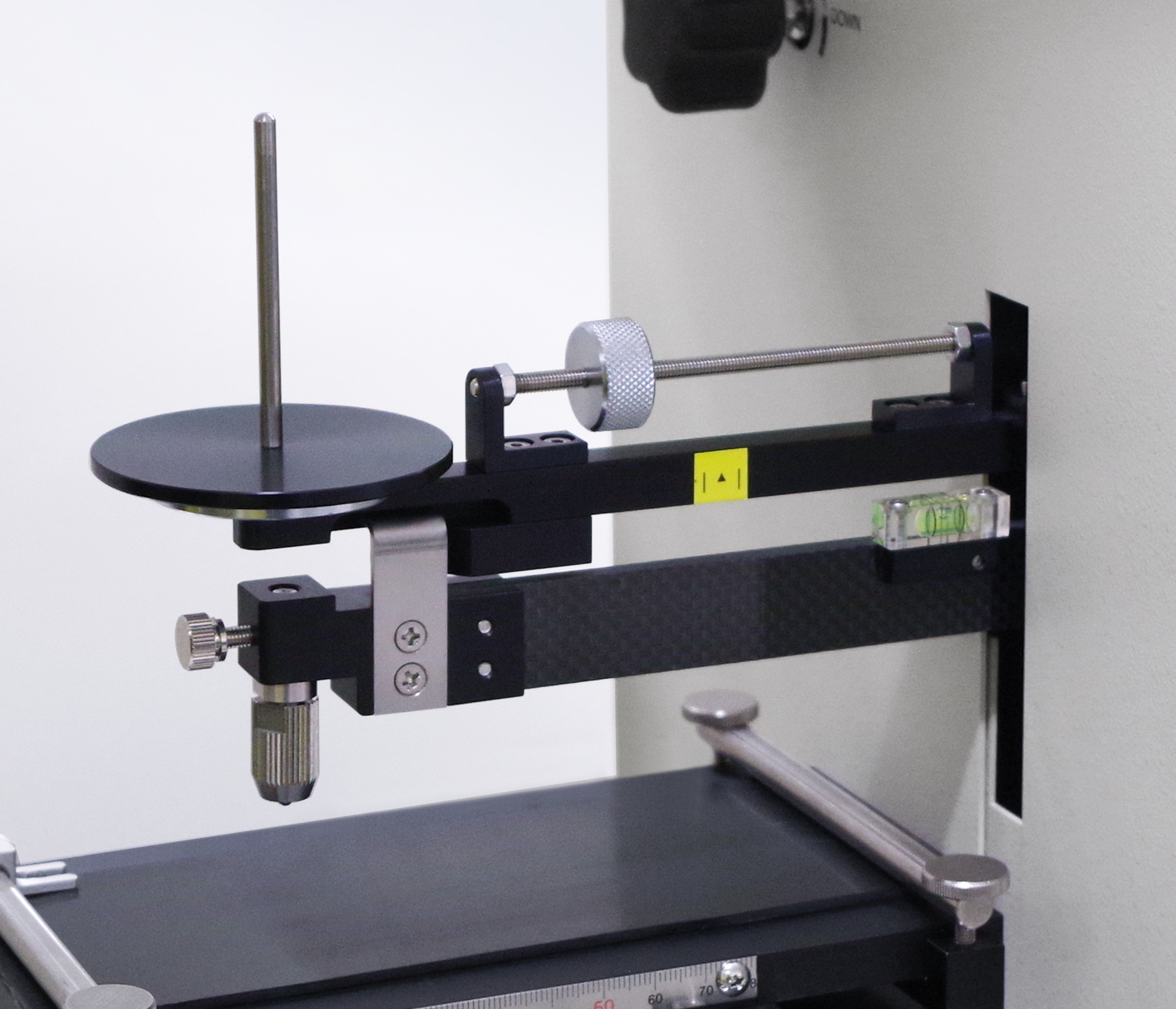

The Triboster TSf-503 is designed for computer-controlled analysis of the static and kinetic coefficient of friction (COF). The highly versatile device, with its linear reciprocating sample stage, can be used for all kinds of samples with different shapes because fixtures can be specially designed according to the sample. The TSf-503 features the unique patented crank-shaped biaxial balance technology for accurate and reliable measurements.

TSf-503 is available with a standard normal load range of 100 to 1.000 g and an optional range of 200 to 2.000 g.

Measurements with different loads, speeds, contact probe geometries, measurement methods, and options allow customers to set up the instruments to meet their special needs.

Measurement of Friction

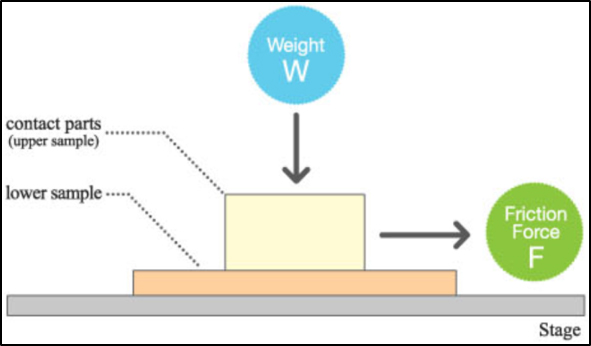

A Friction Analyzer or Friction Tester measures two objects' resistance, or friction force, which slide against each other. The magnitude of the friction and the abrasion depends on material composition, contact geometry, load (normal force), sliding speed, temperature, humidity, surface roughness, etc. The value of the Coefficient Of Friction (COF) “μ” is defined by the relationship between the required force ”F” to slide an object and the load “W” perpendicular to the surface the object is resting on. As the COF is a dimensionless scalar, it has no unit, and the direction of the force does not change its magnitude.

When the stage with the fixed object moves, the load “W” of the object connected to the measuring unit generates the frictional force “F” between the two objects. The measuring unit detects this force, and the software calculates the coefficient of friction "μ".

The kinetic COF follows after overcoming the static COF, so the COF “μ” can be 1) static or 2) kinetic.

1) The static COF "μs" describes the friction force between two objects when neither of the objects is moving.

2) The kinetic COF "μk", or sliding or dynamic COF, describes the friction force between two objects if one object is moving or if two objects are moving against each other.

Non-moving objects experience more friction than moving ones, requiring more force to put them in motion than sustain them. Thus, the static COF is larger than its kinetic counterpart.

The concept of Kyowa's unique balance design

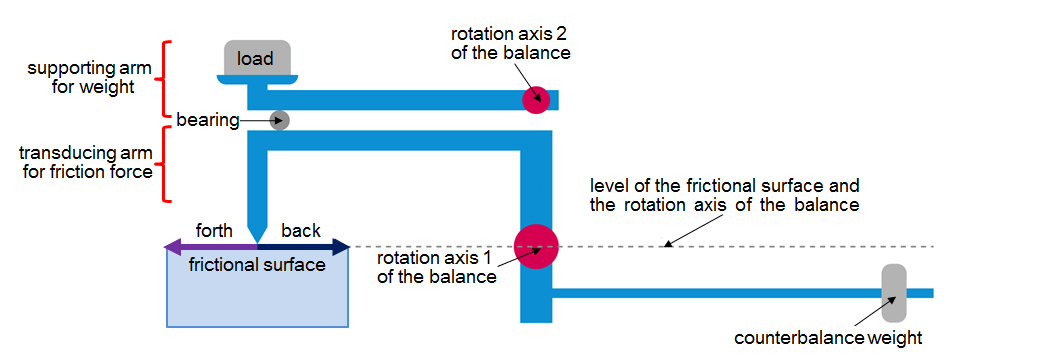

Kyowa's crank-shaped biaxial balance design

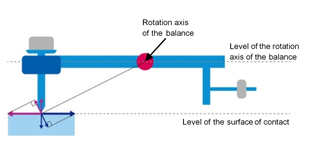

Conventional balance design

One major advantage of this new crank-shaped biaxial balance technology is isolating inertia effects and external forces from the load cell. The upper part of the biaxial balance is a supporting arm for the weight, while the lower part acts as a transducing arm for the friction force to the load cell. Both parts perform their functions individually, properly isolating inertial effects and external forces from the load cell.

Another major advantage is that due to the leveled frictional surface and the rotation axis of the balance, the weight perpendicular to the surface of contact is the same in both directions, back and forth. Therefore, the friction force transduced to the load cell is the same despite different directions.

Implementing the crank-shaped biaxial balance technology to our Triboster TSf-503 results in highly accurate and reliable measurement data unaffected by inertial effects and the sample stage's back-and-forth movement.

Functions and measuring routines

Biaxial balance technology

- Minimizing the effects of inertia and other external forces on the load cell during measurements ensures accurate, reliable results.

Two-way-measurements

- Measurement of the coefficients of friction in both ways of stage travel.

Automatic contact probe lift-up function

- Measurement of the coefficients of friction in only one way of stage travel. The contact probe is lifted automatically after one stroke to avoid contact with the sample when the stage returns.

Seven measurement routines

Various measurement routines are available to ensure maximum flexibility in determining specific sample characteristics.

- Standard repetition

Measuring the coefficients of friction repeatedly on the same measuring area in up to 12 cycles - Continuous static friction

Measuring up to 50 data points of coefficients of static friction in one stroke by the stop-and-go movement of the stage - Repetition dependency

Measuring the coefficients of friction repeatedly on the same measuring area in 100 to 10.000 cycles - Multi-sample

Measuring the coefficients of friction for different samples or different areas of one sample for easy comparison - Load-dependency

Measuring the coefficients of friction depending on different normal loads - Speed-dependency

Measuring the coefficients of friction depending on different speeds - Time-interval dependency

Analyzing the influence of adhesion on the coefficients of friction depending on up to four different contact times in one way by use of the counterpart lift-up function and the stop-and-go movement of the stage

Hardware

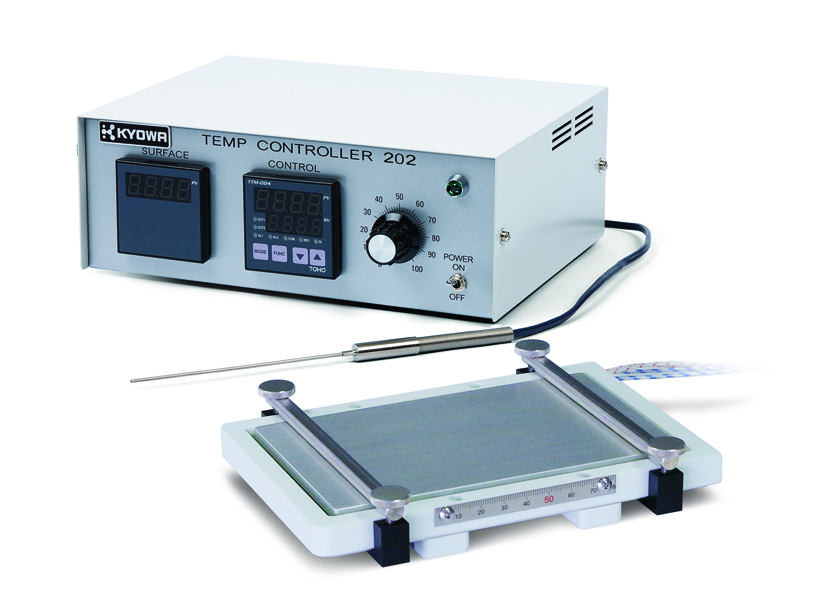

- Heater-type temperature-controlled sample stage for measurements from ambient to +180 ℃

- Jacket-type temperature-controlled sample stage for measurements from +10 to +60 ℃

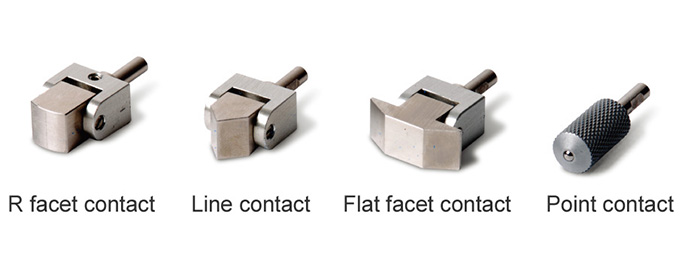

- A wide variety of contact probes with different geometries

- Different weights in the range from 50 to 2.000 g

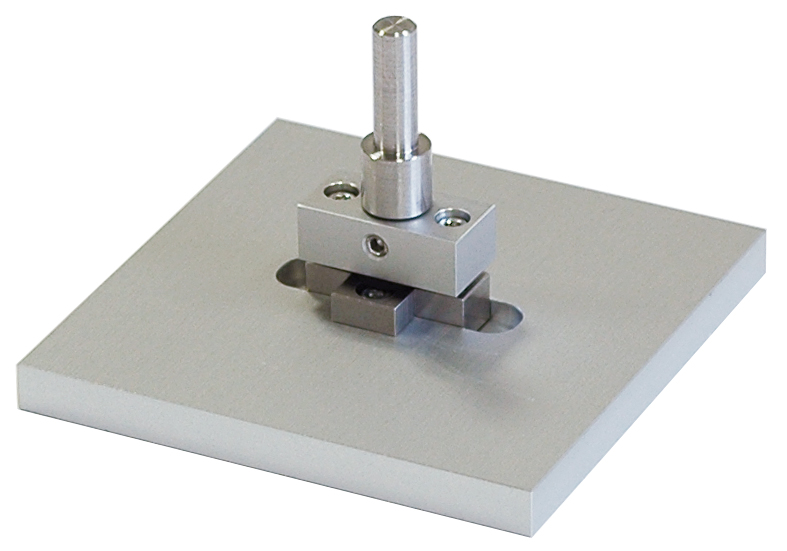

- Special holder for the measurements of pencils

Lubrication oil

- Friction, wear-resistance, and longevity of oil-lubricated metallic surfaces

- Dependence of friction on temperature

Cosmetics

- Longevity and peel resistance of manicures

- The smoothness of hair before and after treatment with hairdressing

- The friction of surfaces from production machines, to improve the flow properties of powders, and to prevent powder adhesion

Powders

- Functionality and effectiveness of powder lubricants

Papers

- The durability of and damage to papers or the surfaces of printing media during the printing process

- Friction between paper sheets to each other and between paper sheets and each part of the printer’s paper feed mechanism for its optimization

Rubbers & Plastics

- Friction and wear of tires against road surfaces

- Stick-slip effect between wiper blades and wet windshields

- Functionality and persistence rubbers for table tennis rackets

- Durability and functionality of the rubber surface of paper-feed or pick-up rollers

Textiles

- Smoothness depending on textile weave patterns

- The efficiency of softening and smoothing agents on textiles

- Slippage of different kinds of fabrics on each other

- Slippage of stockings on insoles

Paints & Coatings

- The strength of plating layers and coated surfaces against scratching, continuous rubbing, sliding, etc.

- Friction and wear of coated surfaces against each other

Medical

- The friction of materials from artificial joints, valves of artificial hearts, and implants

- The friction of catheters submerged in water and the durability of the catheter’s coatings.

Automobile

- Extensibility of car polish or wax on the car body and its effectiveness after drying

- Sliding characteristics between clothing fabrics and seat belts or car seat materials

| TSf-503 | |

| Measuring mode | linear reciprocating |

| Display resolution | coefficient of friction: 0.0001 |

| Friction force range |

standard: 0 to 1.000 gf (9.8N) option: 0 to 2.000 gf (19.6N) |

| Normal load range |

standard: 100 to 1.000 g (in steps of 50 g) optional: 200 to 2.000 g (in steps of 100 g) |

| Stage travel distance | 1 to 80 mm (in steps of 1 mm) |

| Stage travel speed | 0.1 to 100 mm/sec |

| Stage travel cycles | max. 10.000 |

| Measurement routines |

- standard repetition - continuous static friction - repetition dependency - multi-sample - load-dependency - speed-dependency - time-interval dependency |

| Maximum sample size | 180 x 100 x 30 mm |

| Sample stage size | 180 x 100 mm |

| Measuring temperature |

standard: ambient optional: jacket-type: +10 to 60 ℃ heater-stage: ambient to +180 ℃ |

| Instrument dimensions | 310 x 600 x 420 mm |

| Approximately weight | 29.0 kg |

| Electric power: Voltage Frequency Power consumption |

AC 100 to 240 V 50/60 Hz 60 W 125 VA |

| Operating environment |

temperature: +10 to 35 ℃, humidity: 30 to 80 %RH (non-condensing) positioned away from sources of electrical noise and vibration |