The following table describes the differences between the measuring process of each model

| DMo model |

Positioning of first measurement | Generation of droplet | Deposition of droplet (control / recognition) | Analysis of droplet | Positioning of next measurement | Full-scale continuous measurements |

| 502WA | ▲ by rotary knob |

● | ▲ / ● | ● | ▲ | ▲ |

| 702WA | ▲ by command button |

● | ● / ● | ● | ● | ▲ |

| 902WA | ● | ● | ● / ● | ● | ● | ● |

▲ manual ● automatic

- Fast image capturing system with standard 400 fps at 640x480 resolution USB3.0 CMOS camera, max. 2700fps at 640x64 resolution

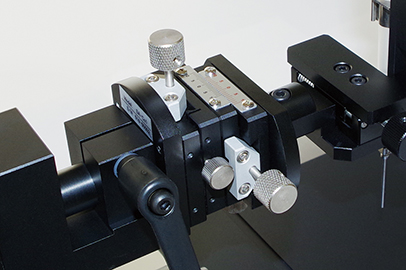

- Automatic single dispenser system with a set of 5 glass syringes and 5 SUS needles for precise adjustment of droplet volume and quick refilling and replacement of liquid samples

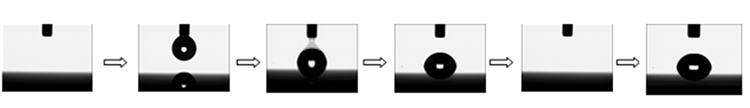

- Automatic recognition of drop deposition

- Live image display and droplet volume monitoring

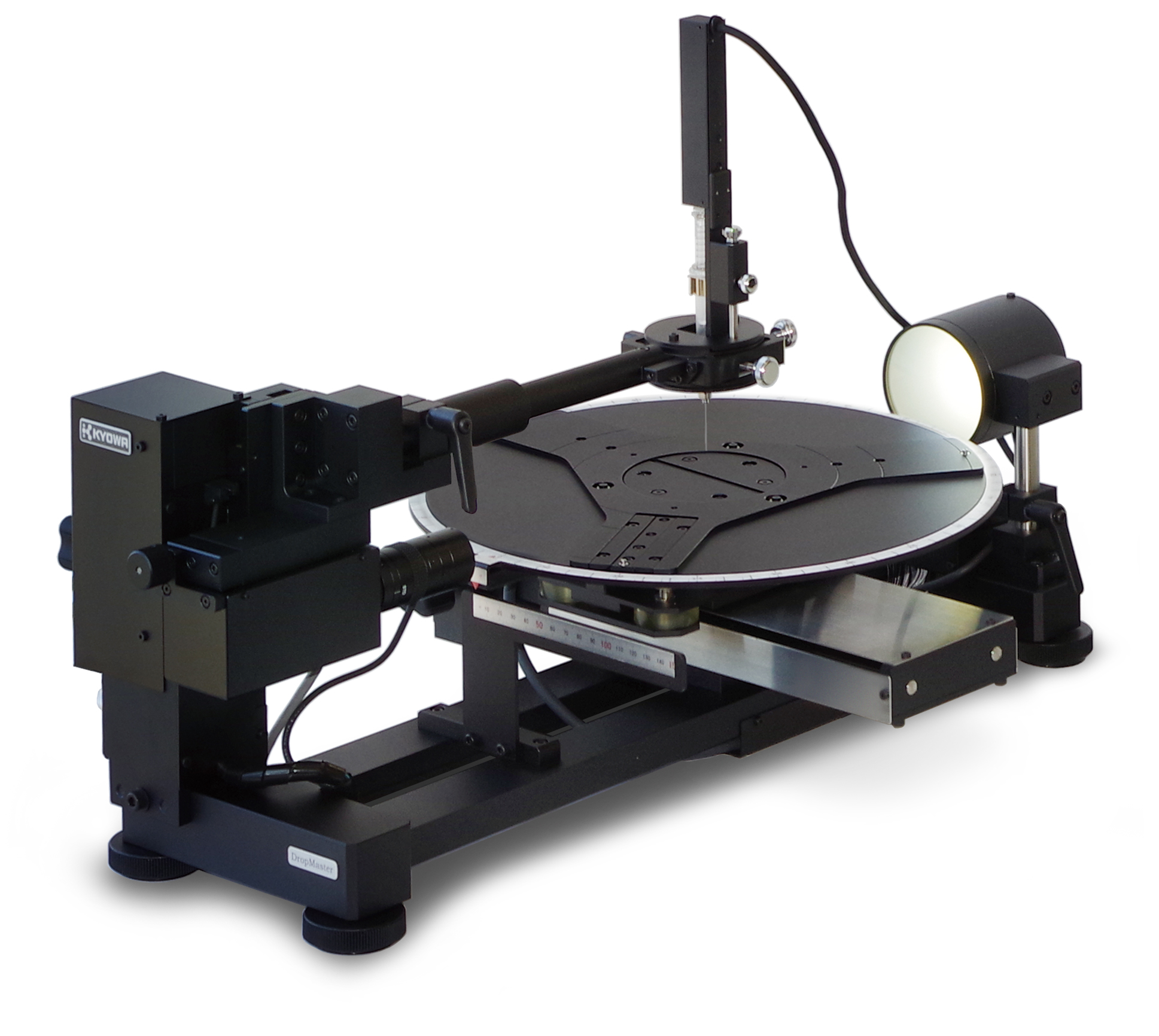

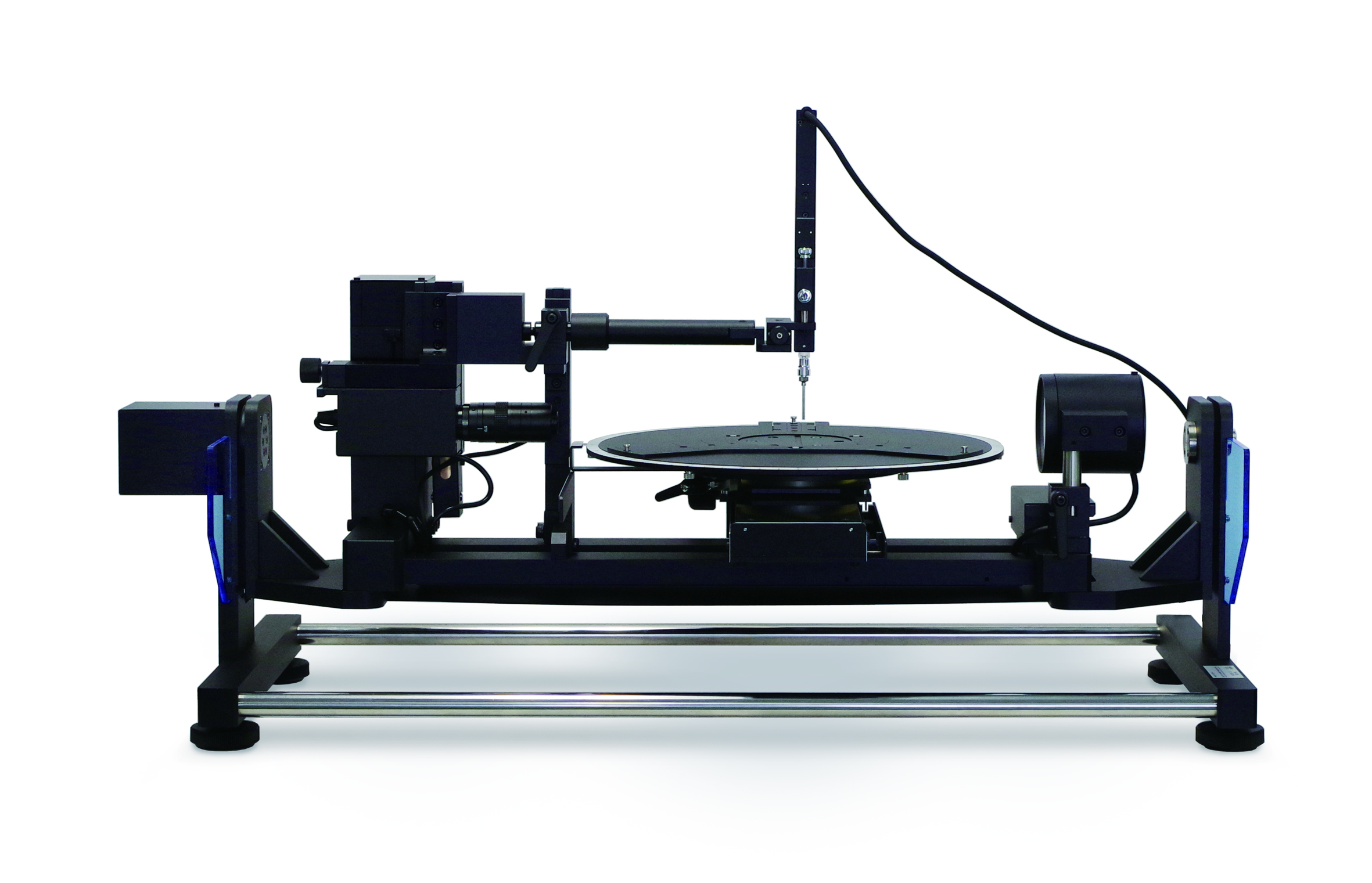

- Diameter 335mm 360º rotation sample stage with a maximum load capacity of 0.4kgs

- Fine adjustable stage travel for exact positioning, travel distance: x-axis: 150mm, y-axis: fixed, z-axis: fixed

- Focusing aid with displayed index graph and value and brightness adjustment to achieve perfect focus

- Movie converter to convert data images to MPEG-1 or AVI movie format

- Determination of contact angles, droplet volume, residual droplet volume, sessile drop volume, height, and radius of the sessile drop

- Measured results are displayed in a spreadsheet for easy reference and comparison, and saved in CSV format for easy export to and manipulation in MS Excel

- User-specified analysis report function, providing measurement results and parameters

- Adjustable level of the body and stage

- Droplet calibration standard for standard view, bearing one full circle for calibration and three droplet silhouettes of 5º, 60º, and 108º for periodic inspection of measurement accuracy

Hardware

- Tilting stage for measurements of roll-off angles, incl. FAMAS software add-in [Sliding method] (except 902WA)

- Add-on module [Dynamic sliding method] to measure roll-off speed and roll-off acceleration. Only in combination with the tilting stage package (except 902WA)

- Multi-manual dispenser holder

- Multi-automatic dispenser system

- Large capacity pump dispenser, incl. a 50μl liquid container

- Surface free energy kit

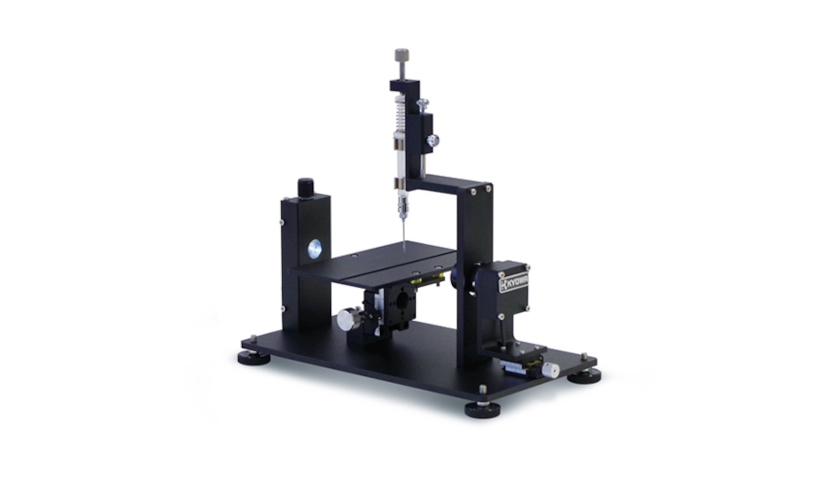

- Pendant drop kit (for standard & wide view)

- Droplet calibration standard (for wide 1 view)

- Pendant drop kit (for standard & wide view)

- Kit for captive-bubble-measurements

- Pendant drop calibration standard (for standard view)

- Pendant drop calibration standard (for wide 1 and wide 2 view)

- Surface cleanliness and homogeneity after cleaning processes (typically for removal of organic contaminations)

- Surface properties such as wettability and adhesion of modified surfaces and thin film coatings

- Wetting and dewetting properties in immersion lithography processes using the sliding method with external tilting stage and/or using the extension/contraction method

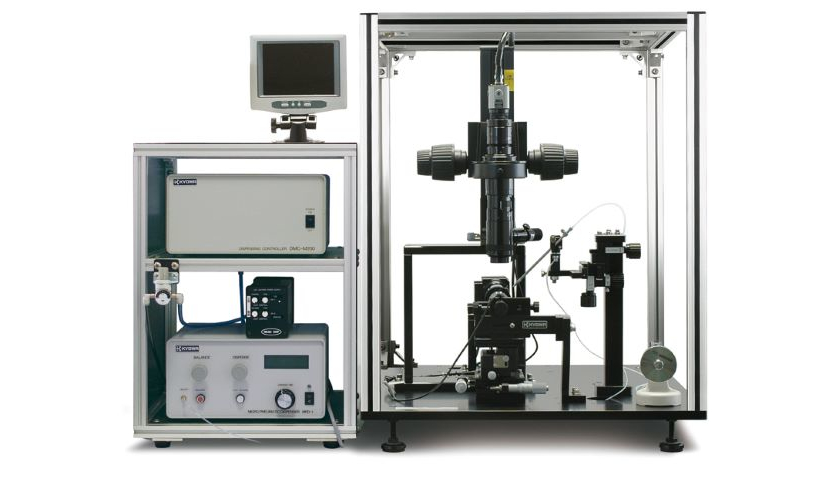

| DMo-902WA | DMo-702WA | DMo-502WA | |

| Camera system |

USB3.0 CMOS camera with: 400fps at 640x480 pixels 500fps at 640x400 pixels 1000fps at 640x200 pixels 2700fps at 640x64 pixels |

||

| Optical system |

focus: manual focus with 3-step manual zoom field of view: 6.1x4.7mm, 11.1x8.2mm, 15.8x11.8mm ±6% |

||

| Measuring methods |

contact angle: sessile drop (static & dynamic), advancing/receding, tilting1) surface/interfacial tension: pendant drop (static & dynamic) |

||

| Analysis methods |

contact angle: θ/2, tangent, curve fitting (ellipse, circle) surface/interfacial tension: Young-Laplace, ds/de surface free energy of solids: OWRK, Owens-Wendt, Kaelble-Uy, Kitazaki-Hata, Wu, acid-base, Zisman |

||

| Measuring range |

contact angle: 0 to 180° surface/interfacial tension: 0 to 2000mN/m |

||

| Resolution |

contact angle: 0.01° surface/interfacial tension: 0.01mN/m |

||

| Accuracy2) |

contact angle: 0.2° surface/interfacial tension: 0.2mN/m |

||

| Maximum sample surface area and height (Dia.xH) | max. 300x35mm |

||

| Maximum sample weight | 400g | ||

| Sample stage operation: X-axis Y-axis Z-axis Rotation axis |

150mm (aut.) --- --- 360° (aut.) |

150mm (aut.) --- --- 360° (man.) |

150mm (man.) --- --- 360° (man.) |

| Dispenser operation: Z-axis Droplet deposition Droplet generation Dispensing resolution |

35mm automatic automatic 0.1μl |

35mm automatic automatic 0.1μl |

35mm manual automatic 0.1μl |

| Measuring temperature | ambient | ||

| Dimensions (WxDxH) of: Main instrument Control box |

375x684x432mm 290x240x100mm |

375x684x432mm 260x200x70mm |

|

| Approximately weight of: Main instrument Control box |

12.5kg 4.3kg |

11.0kg 4.3kg |

10.0kg 1.6kg |

| Electric power: Voltage Frequency Power consumption |

AC100-240V 50/60 Hz 115W 120VA |

AC100-240V 50/60 Hz 25W 48VA |

|

| Operating environment |

temperature: +10 to +35℃, humidity: 30-80%RH (non-condensing) positioned away from sources of electrical noise and vibration |

||

1) An optional external tilting stage is required

2) Accuracy is the repeatability in terms of standard deviation based on the manufacturer’s calibration standard

Related Products

Details of FAMAS software