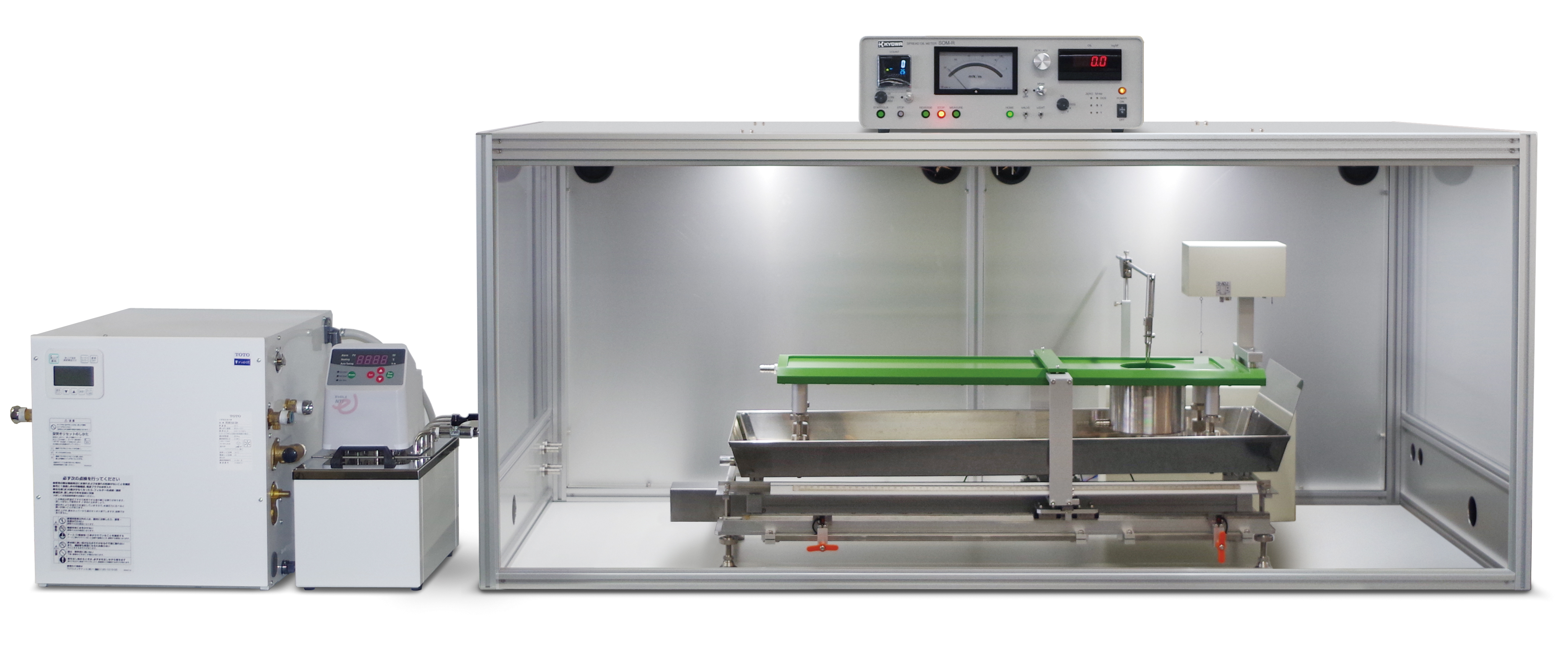

SOM-R

Spread oil meter/surface pressure-area isotherm

During the production of rolled steel, tin, or aluminum sheets, oils such as DOS, CSO, or ATBC are used as a coating medium to prevent sheets from rusting. Monitoring the amount of oil coated on the sheets is essential to ensure the production of high-quality metal sheets.

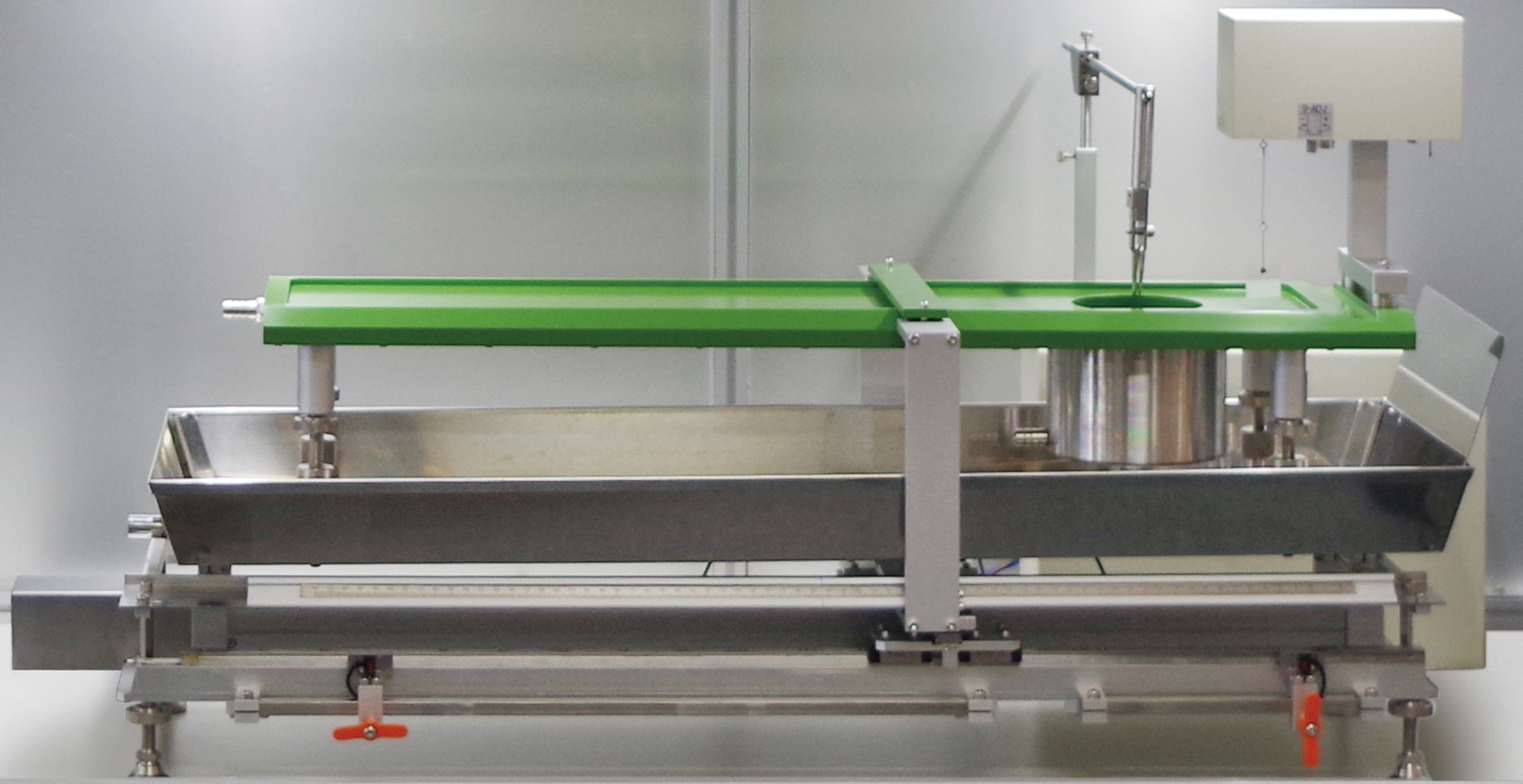

Using test metal sheets from the production line, our Automatic Spread Oil Meter SOM-R determines the oil amount by transferring the oil coated on the rolled metal test sheets onto a water surface and detecting the change of the surface film pressure.

Features

- Utilization of the Wilhelmy plate method to precisely detect the surface film pressure and to determine the oil volume in the range of μg on a test metal sheet

- Two independent temperature control systems to ensure reliable results and high repeatability even in difficult measuring environments

- Indication of the oil volume in mg/m2 on a LED display

- Easy to clean Teflon-coated trough with excellent corrosion resistance

- Easy to clean measuring probe (glass plate)

- Periodical calibration of the balancing system can easily be done by the user

Options

- Step down voltage transformer to convert foreign voltages to AC100V of the SOM-R

Applications

- Monitoring the amount of the oil coated on rolled steel, tin, or aluminum sheets

Specifications

Main Unit

| SOM-R | |

| Electric power: Voltage Frequency Total power consumption |

AC100 50/60 Hz 2.7kW |

| Operating environment |

Temperature: +10 to +35℃, humidity: 30-80%RH (non-condensing) Positioned away from sources of electrical noise and vibration |

| Total footprint | 2400x800mm |

Individual components

| Control Box | |

| Surface Film Pressure | |

| Measuring method | Wilhelmy plate method |

| Measuring range | 0 to 50.0mN/m (analog meter) |

| Accuracy | ±0.5%FS |

| Oil Volume | |

| Measuring range |

0.3 to 17.5mg/m2 (based on a dia. 60mm specimen with DOS oil) |

| Oil volume range | 0.7 to 50.μg |

| Digit & Resolution | 0.1mg/m2 |

| Display method | LED digital display |

| Accuracy | ±2.0%FS (based on +35℃) |

| Preset oil types | Up to three types |

| Dimensions (WxDxH) | 430x2305x150mm (body only, excluding protrusion) |

| Weight | 5.5kg |

| Oil Film Spreading Trough | |

| Internal Dimensions (WxDxH) |

700x140x5mm |

| Dipping Well Dimensions (dia.xH) |

90x90mm |

| External Dimensions (WxDxH) |

775x180x115mm |

| Weight | 10.2kg |

| Barrier Transfer Unit | |

| Barrier Speed |

300mm/min during compression 600mm/min during reversing |

| Dimensions (WxDxH) | 945x335x295mm |

| Weight | 21.4kg |

| Environmental Chamber | |

| Dimensions (WxDxH) | 1300x650x700mm |

| Automatic Sample Dipping Unit | |

| Dipping repetitions | 1 to 999999 |

| Dipping speed range (one complete cycle) |

High: 1.7sec Low: 6.0sec Adj: 0.96sec to ∞ |

| Dimensions (WxDxH) | 330x145x380mm (body only, excluding protrusion) |

| Weight | 7.2kg |

| Refrigerating & Heating Water Circulator | |

| Temperature range | +5℃ above RT to +95℃ |

| Control accuracy | ±0.05℃ |

| Control method | PID |

| Safety functions |

Diagnosis functions (max/min temperature abnormality, heater breakage, sensor abnormality) |

| Heater capacity | 1.1kW |

| Bath volume | 5.5L |

| Circulation pump | Max. 5L/min |

| Tubing diameter of inlet/outlet |

10mm |

| Dimensions (WxDxH) | 195x305x360mm |

| Weight | 8kg (13.5kg being water-filled) |

| Heated Water Supply System | |

| Temperature range | +30 to +70℃ |

| Control accuracy | ±5.0℃ |

| Control method | Thermistor |

| Safety functions | Temperature fuse, manual reset |

| Heater capacity | 1.1kW |

| Bath volume | 25L |

| Pressure reducing valve | 0.08MPa |

| Dimensions (WxDxH) | 434x395x395mm |

| Weight | 13kg (38kg being water-filled) |

Partial list of customers

The following is a partial list of our valued customers, including some of the most prestigious and largest steel-producing companies in the world, who use our Automatic Spread Oil Meter in their production lines, reflecting the quality and reliability of our product.

- Baosteel

(China) - China Steel

(Taiwan) - CSEMC

(China) - Eregli Iron & Steel Works

(Turkey) - Fujian Goomax Metal

(China) - Furukawa Electric

(Japan) - Guangzhou Pacific Tinplate

(China) - Hainan Haiwoo Tinplate

(China) - HBIS Group

(China) - JFE Steel

(Japan) - JSW Steel Coated Products

(India) - JSW Vallabh Tinplate Private

(India) - Kobe Steel

(Japan) - Nippon Steel

(Japan) - Perstima Tinplate

(Malaysia, Vietnam) - POSCO

(Korea) - PT. Multi Pratama Sarana

(Indonesia) - Siam Tinplate (STP)

(Thailand) - Siderar S.A.I.C.

(Argentina) - Shin-Hwa Silup

(Korea) - Showa Aluminum Can

(Japan) - Tinplate Company of India

(India) - Ton Yi Industrial Corp.

(Taiwan & China) - Toyo Kohan

(Japan) - Toyo Seikan

(Japan) - UACJ

(Japan & Thailand) - Wuxi Zhongcai New Materials

(China)