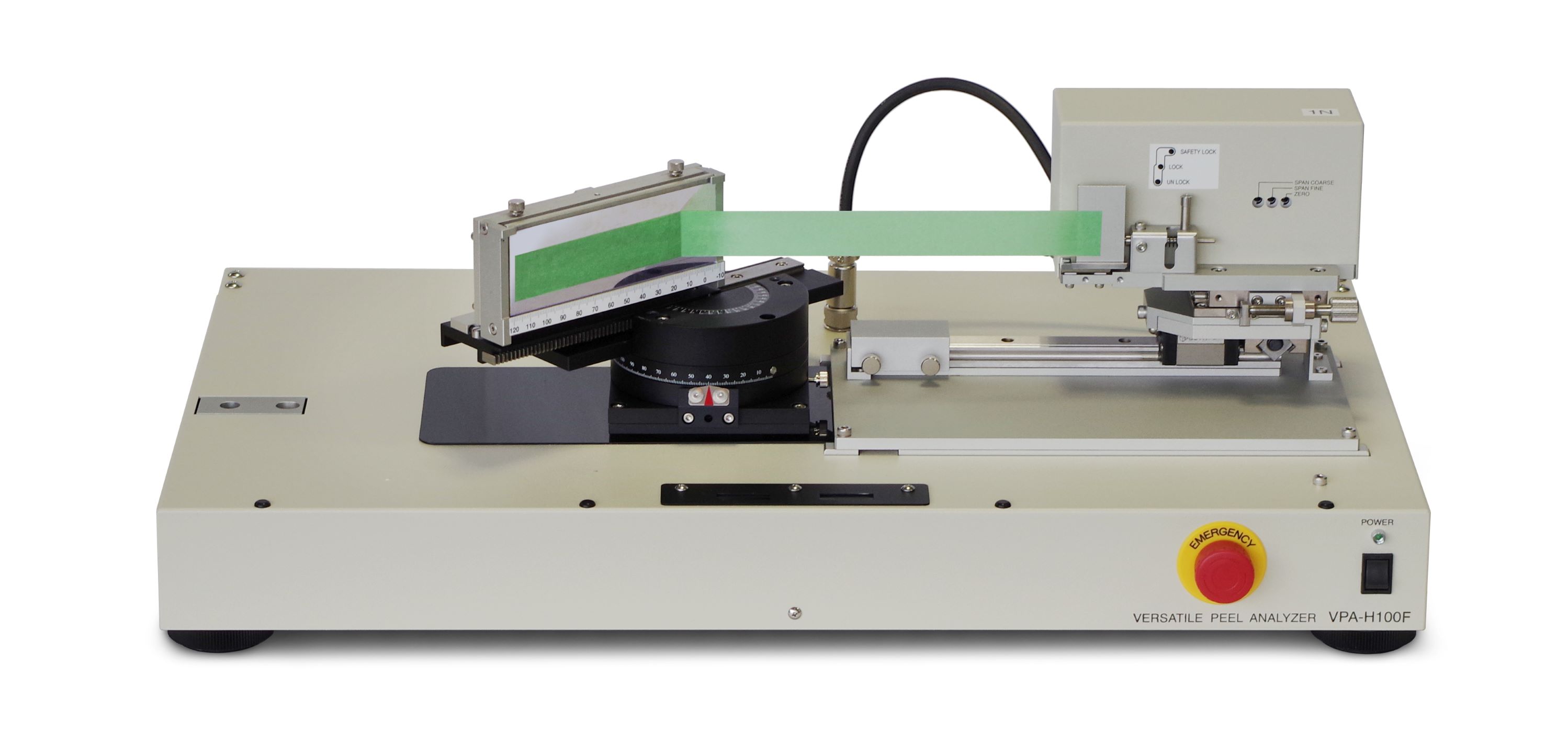

With the development of our Versatile Peel Analyzer VPA series, measurements, once impossible or hardly achieved with conventional tensile strength testers, have finally become possible. When equipped with our low force load cell with a full scale rated capacity of only 0.1 N, even minuscule peel strengths as low as 0.001 N can be measured and easily compared.

The most remarkable feature of our Versatile Peel Analyzer VPA series is that the peel behavior of composite materials, such as packaging materials, laminated materials, laminated films, coating films, ceramic green sheets, etc., can be evaluated under freely adjustable peel angles from 0 to 180 º using Kyowa’s unique proprietary 'Flat Plate Cross Stage Method' and self-developed analysis software.

While the standard VPA-H200 model and the compact-sized VPA-H100 model share the same functions and features, the VPA-H200's sample stage, with a length of 200 mm, allows for an effective peel distance twice that of the VPA-H100. The sample stage's maximum speed of 30.000 mm/min allows for a peel rate 2.5 times higher than that of the VPA-H100.

Peel Strength Testing

Pressure-sensitive adhesive tapes, or PSA tapes, play significant roles as constitutive and integral parts of production processes in various forefront industries such as flat panel displays, semiconductors, optical instruments, solar batteries, automobiles, architecture, and medical treatments.

The peel adhesion, shear resistance, and tack tests characterize the performance of PSA tapes. The widespread peel adhesion test delivers an objective appraisal with quantitative evaluation following international standards ISO 8510-1 and 2, the 90 º peel test, and the 180 º peel test. The 180 º peel test tends to be affected slightly by the thickness and elasticity of PSA tape, and the 90 º peel test may experience elongation and sagging of PSA tape due to the somewhat complicated structure of the jigs.

Demands on peel adhesion, peel angle, and peel rate for optimizing adhesive tapes used in production processes vary widely depending on the applications.

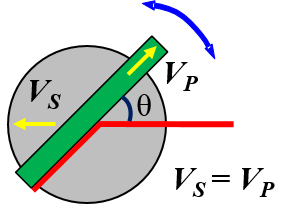

KYOWA’s patented Flat Plate Cross Stage Method

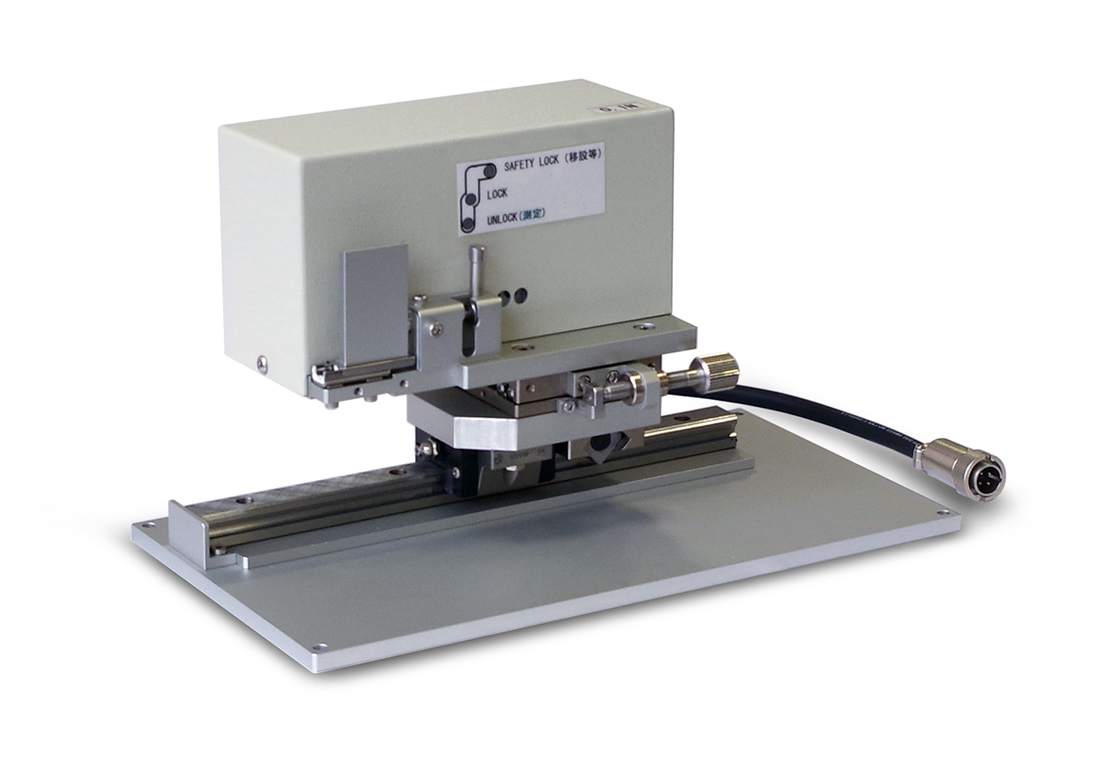

The flat specimen stage sits on a rotary table, with which the peel angle can be swiftly adjusted from 0 to 180 º without using jigs or tools. The synchronized actuator mechanism maintains the same peel rate and angle during the stage travel. No complex adjustments and calculations are required.

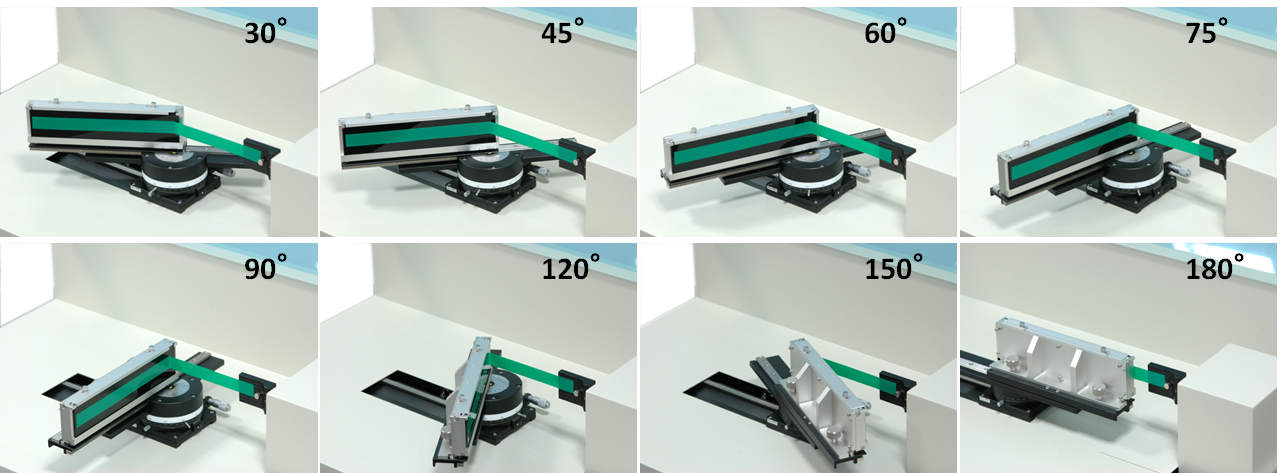

Quick and easy setting of the peel angle

Peel angles can be changed quickly and easily without extra jigs or tools within a few seconds. To change the peel angle, loosen the locking screw of the rotary table, adjust the desired peel angle according to the affixed angular scale, and tighten again the locking screw. That's how simple it is!

Demonstrations of peel tests at different peel angles

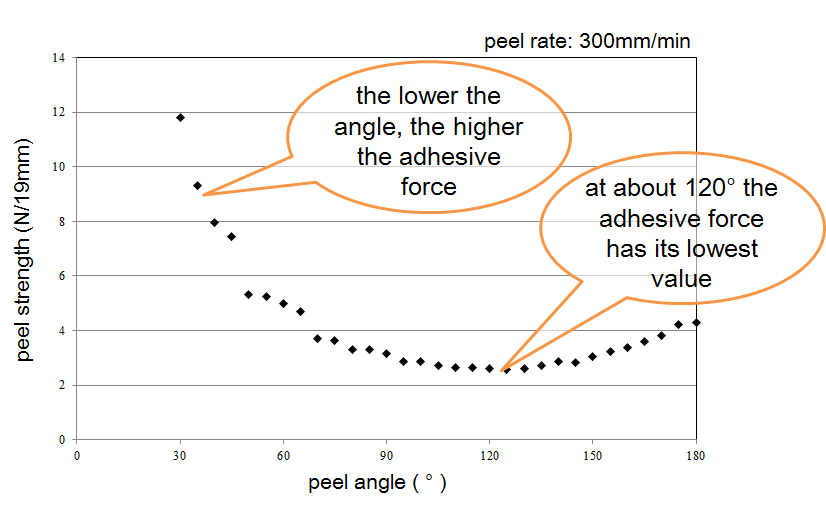

Example of peel strength data

The graph shows an adhesive tape's typical peel strength curve depending on peel angles. At a peel angle of 30 º, the peel strength has its highest value, decreasing gradually with higher peel angles up to about 120 º. A turning point can be seen here, from which the peel strength slightly increases gradually with higher angles.

- Peel angles between 0 and 180º

- Peel rates from 3 up to 30.000 mm/min

- Effective peel area of up to 40 x 200 mm

- Quick and easily exchangeable load cell units (0.1 N, 1 N, 5 N, 10 N, 50 N, and 100 N full scale rated capacity) incl. calibration kit

- Overload protection (at 90 % of the full-scale rated capacity of the load cell)

- Emergency stop button

Hardware

- Heater-type temperature-controlled sample stage for measurements from ambient to +180 ℃

- Jacket-type temperature-controlled sample stage for measurements from +10 to 70 ℃

- Protective cover with an optional interlock safety switch

- 2 kg manual hand roller for preparing tapes

- Peel behavior observation by a special camera system

- Equipment for tensile strength testing (applicable only with 50 N or 100 N load cell units)

- A wide variety of different kinds of grips, such as pneumatic grips

- Special sample stage for 180 º peel tests

- Effects of peel angles and peel rates on peel behavior of PSA tapes, packaging films, labels, release papers/films

- Peeling properties between carbon fiber prepregs and release papers

- Releasing strength between protective films and critical surfaces such as phone displays, glasses, metals, carpets

- Peel/bond strength between laminated film layers, holograms on plastic cards, coating films on glass or metal, adhesive tapes on silicon wafer and frames

- Adhesive strength between thin-film electrodes and current collectors in lithium-ion batteries

- Adhesive strength between ceramic green sheets and carrier films for laminated ceramic capacitors

- Visualization/observation of the peeling process from above and behind the adherend

- Low force tensile strength tests of various films

| VPA-H100F | VPA-H200F | |

| Measuring method | Flat Plate Cross Stage Method | |

| Rated capacity (full scale) load cell units |

0.1 N, 1 N, 5 N, 10 N, 50 N, 100 N |

|

| Maximum measuring load | 90 % of the load cell’s rated capacity | |

| Display resolution of load cell units |

0.1 N, 1 N, 5 N, 10 N: 0.001 N 50 N, 100 N: 0.01 N |

|

| Adherend sample shape: Dimensions (WxL) Maximum thickness |

flat sheet, plate, or strip 50 x 130 mm 3 mm |

flat sheet, plate, or strip 50 x 230 mm 3 mm |

| Max. peel area (WxL) | 40 x 100 mm | 40 x 200 mm |

| Stage travel speed range (Vs) | 3 to 12.000 mm/min | 3 to 30.000 mm/min |

| Max. stage travel distance (Ds) | 100 mm | 200 mm |

| Default sampling rate 1) | every 0.20 mm | every 0.25 mm |

| Peel rate (Vp) |

Vp=Vs (Peel rate=Stage travel speed) the peel rate is independent of the peel angle |

|

| Peel rate dependency |

measurement of one peel rate or gradually changed peel rates within one measurement cycle |

|

| Peel angle dependency | measurement of any peel angle between 0 and 180° | |

| Analysis contents |

- peel force versus peel distance - peel force versus peel rate - peel force versus peel angle |

|

| Dimensions (WxDxH) | 620 x 400 x 270 mm | 910 x 550 x 270 mm |

| Approximately weight | 25 kg | 41 kg |

| Electric power: Voltage Frequency Power consumption |

AC 100 to 240 V 50/60 Hz 25 W 65 VA |

|

| Operating environment |

temperature: +10 to +35 ℃, humidity: 30 to 80 %RH (non-condensing) positioned away from sources of electrical noise and vibration |

|

1) For both models, the sampling rate can be set to 0.10 mm for peel rates up to 6.000 mm/min and 0.05 mm for up to 3.000 mm/min.