The four models of the DMo series are high-performance contact angle meters, only differing in their grade of automation. The high-speed camera and computer-controlled dispenser allow for precise measurements of static and dynamic contact angles, surface and interfacial tension of liquids, as well as analysis of surface free energy of solids. A wide range of options are available and lower grade models can also be upgraded later.

Citations

Our devices are widely recognized as benchmark tools across various scientific and research fields.

This acknowledgment is solidified by their frequent citation in numerous scholarly publications.

We encourage you to explore the articles below, highlighting our technology's extensive use and impact.

Feel free to download and share them within your networks.

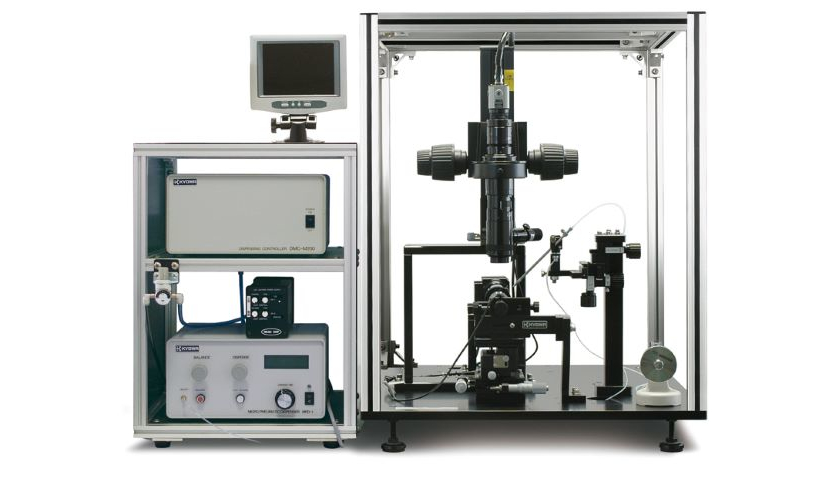

Product Promotion Video

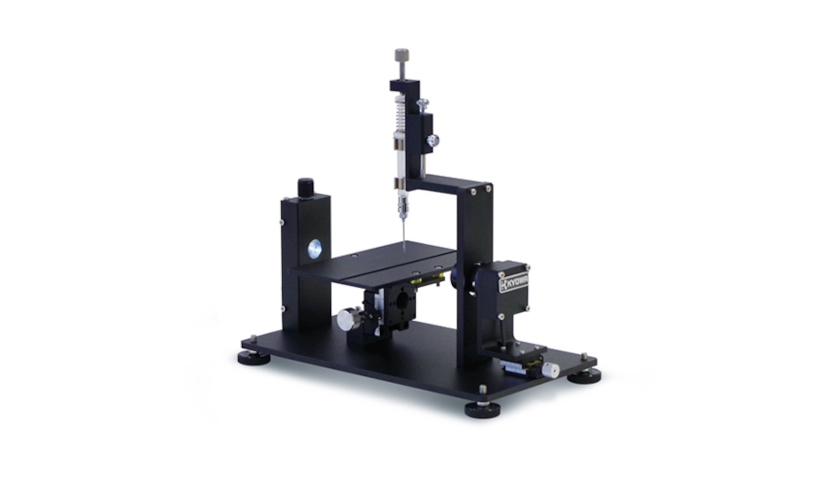

DMo-702

This 11-minute video provides a comprehensive overview of the functions and benefits of the Kyowa DMo-702.

The following table describes the differences between the measuring process of each model

| DMo model |

Positioning of first measurement | Generation of droplet | Deposition of droplet (control / recognition) | Analysis of droplet | Positioning of next measurement | Full-scale continuous measurements |

| 502 | ▲ by rotary knob |

● | ▲ / ● | ● | ▲ | ▲ |

| 602 | ▲ by rotary knob |

● | ● / ● | ● | ▲ | ▲ |

| 702 | ▲ by command button |

● | ● / ● | ● | ● | ▲ |

| 902 | ● | ● | ● / ● | ● | ● | ● |

▲ manual ● automatic

- Fast image capturing system with standard 400 fps at 640x480 resolution USB3.0 CMOS camera, max. 2700fps at 640x64 resolution

- Automatic single dispenser system with a set of 5 glass syringes and 5 SUS needles for precise adjustment of droplet volume and quick refilling and replacement of liquid samples

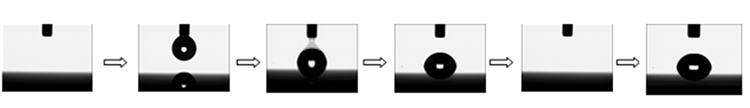

- Automatic recognition of drop deposition by FAMAS analysis software

- Live image display and droplet volume monitoring

- 150x150mm wide sample stage with a maximum load capacity (temperature chamber + sample) of 1.4kgs

- Fine adjustable stage for exact positioning, travel distance: x-axis: 150mm, y-axis: 75mm, z-axis: fixed

- Focusing aid with displayed index graph and value and brightness adjustment to achieve perfect focus

- Movie converter to convert data images to MPEG-1 or AVI movie format

- Determination of contact angles, droplet volume, residual droplet volume, sessile drop volume, height, and radius of the sessile drop

- Measured results are displayed in a spreadsheet for easy reference and comparison, and saved in CSV format for easy export to and manipulation in MS Excel

- User-specified analysis report function, providing measurement results and parameters

- Adjustable level of the body and stage

- Droplet calibration standard for standard view, bearing one full circle for calibration and three droplet silhouettes of 5º, 60º, and 108º for periodic inspection of measurement accuracy

Hardware

- Jacket- and heater-type chambers for temperature measurements from +10 to +380℃ 1)

- Heater-type dispenser for temperature measurements from ambient to +380℃ 1)

- Tilting stage for measurements of roll-off angles, incl. FAMAS software add-in [Sliding method] 1)

- Add-on module [Dynamic sliding method] to measure roll-off speed and roll-off acceleration. Only in combination with the tilting stage package. 1)

- Multi-manual dispenser holder

- Multi-automatic dispenser system

- Large capacity pump dispenser, incl. a 50ml liquid container

- Surface free energy kit

- Pendant drop kit (for standard & wide view)

- Kit for captive-bubble-measurements

- Droplet calibration standard (for wide 1 view)

- Pendant drop calibration standard (for standard view)

- Pendant drop calibration standard (for wide 1 and wide 2 view)

- Determination of wettability of surfaces like glass, metal, plastics, ceramics at ambient temperature

- Surface cleanliness

- Determination of surface and interfacial tension using the Pendant drop kit (standard and wide view)

- Analysis of Surface free energy of solids

- Determination of dynamic contact angles (advancing/receding angles and roll-off angle)

- Coating property, Repellency, Characterization of droplet hysteresis

- Initial spreading, absorbing property, effect of surface active agents

- Adhesive property, characterizing surface modification, digitalization of hydrophilicity/hydrophobicity

| DMo-902 | DMo-702 | DMo-602 | DMo-502 | |

| Camera system |

USB 3.0 CMOS camera with: 400fps at 640x480 pixels 500fps at 640x400 pixels 1000fps at 640x200 pixels 2700fps at 640x64 pixels |

|||

| Optical system |

focus: manual focus with 3-step manual zoom field of view: 6.1x4.7mm, 11.1x8.2mm, 15.8x11.8mm ±6% |

|||

| Measuring methods |

contact angle: sessile drop (static), advancing/receding angle (dynamic) sliding angle (dynamic) 1) surface/interfacial tension: pendant drop (static and dynamic) |

|||

| Analysis methods |

contact angle: θ/2, tangent, curve fitting (ellipse, circle) surface/interfacial tension: Young-Laplace, ds/de surface free energy of solids: OWRK, Owens-Wendt, Kaelble-Uy, Kitazaki-Hata, Wu, acid-base, Zisman |

|||

| Measuring range |

contact angle: 0 to 180° surface/interfacial tension: 0 to 2000mN/m |

|||

| Resolution |

contact angle: 0.01° surface/interfacial tension: 0.01mN/m |

|||

| Accuracy2) |

contact angle: 0.2° surface/interfacial tension: 0.2mN/m |

|||

| Maximum sample surface area and height (WxDxH) | 150x150x16mm |

150x150x35mm |

||

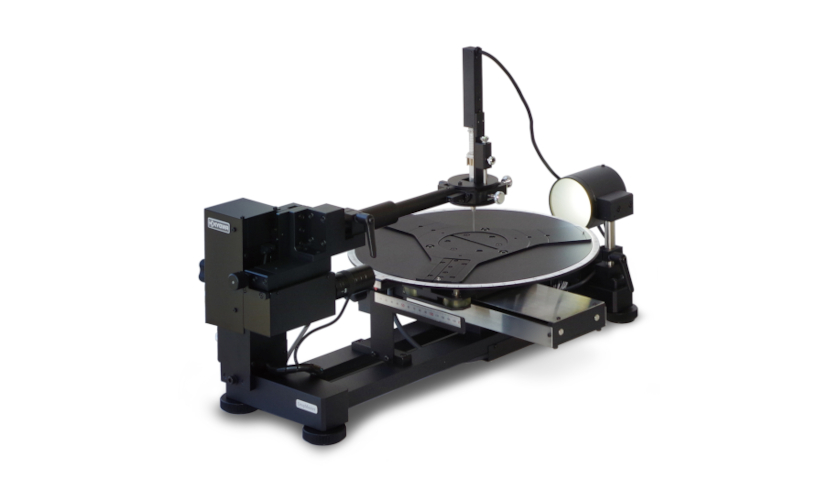

| Sample stage operation: X-axis Y-axis Z-axis Rotation axis |

150mm (aut.) 75mm (aut.) --- 360° (aut.) |

150mm (aut.) 75mm (man.) --- --- |

150mm (man.) 75mm (man.) --- --- |

|

| Dispenser operation: Z-axis Droplet deposition Droplet generation Droplet resolution |

16mm automatic automatic 0.1μl |

35mm automatic automatic 0.1μl |

35mm manual automatic 0.1μl |

|

| Dimensions (WxDxH) of: Main instrument Control box |

297x544x305mm 290x240x86mm |

288x544x305mm 260x200x70mm |

||

| Approximately weight of: Main instrument Control box |

10.0kg 4.3kg |

8.5kg 4.3kg |

7.5kg 1.5kg |

|

| Electric power: Voltage Frequency Power consumption |

AC100-240V 50/60 Hz 115W 120VA |

AC100-240V 50/60Hz 25W 48VA |

||

| Operating environment |

temperature: +10 to +35℃, humidity: 30-80%RH (non-condensing) positioned away from sources of electrical noise and vibration |

|||

1) An optional external tilting stage is required

2) Accuracy is the repeatability in terms of standard deviation based on the manufacturer’s calibration standard