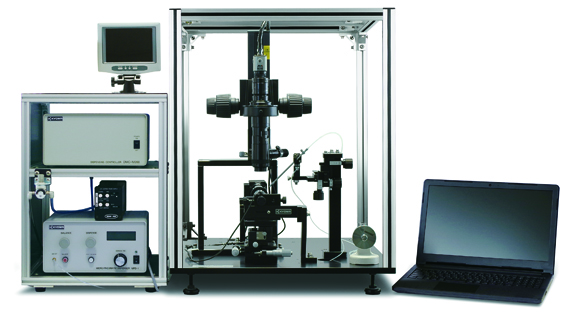

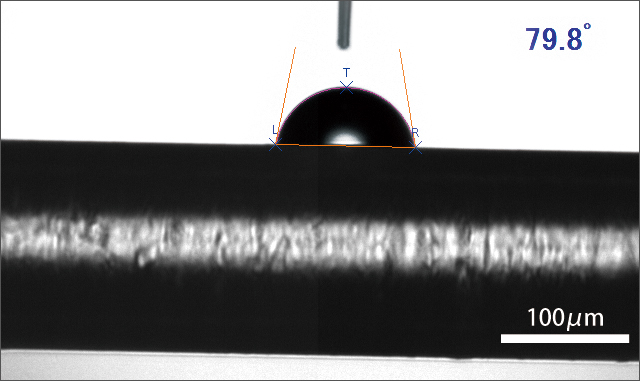

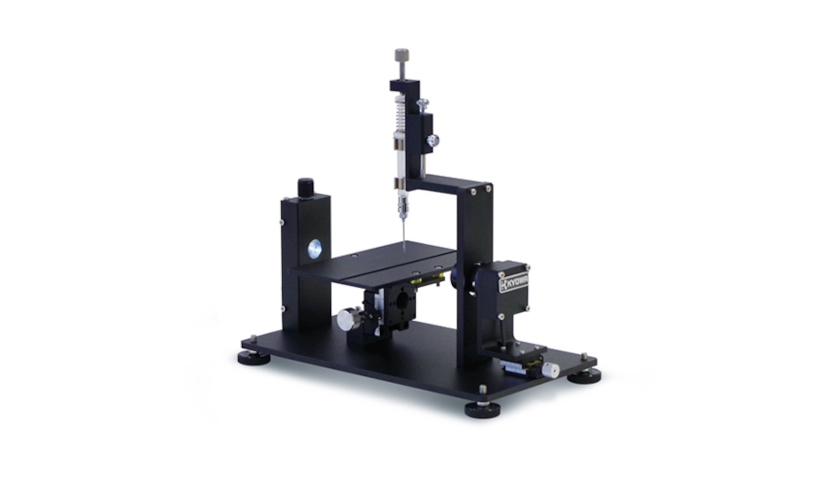

The MCA-4 uses a precise electric micro-injector system and a high-quality optical system for accurate contact angle measurements of micro-droplets on small surface areas of only 100 x 100µm. With special capillaries available with three different inner diameters, micro-droplets in a range of about 10 to 1000pL can be produced with high reproducibility. This state-of-the-art system is equipped with an additional top-view camera that enables the deposition of droplets with pinpoint accuracy and the observation of the three-phase line and the spreading of micro-droplets on solid surfaces.

Citations

Our MCAs aren't just tools; they're recognized benchmarks across a wide range of scientific and research applications.

Their frequent citation in scholarly publications speaks volumes about their impact and reliability.

We invite you to explore, download, and share the supporting articles below to see why our technology is trusted by researchers worldwide.

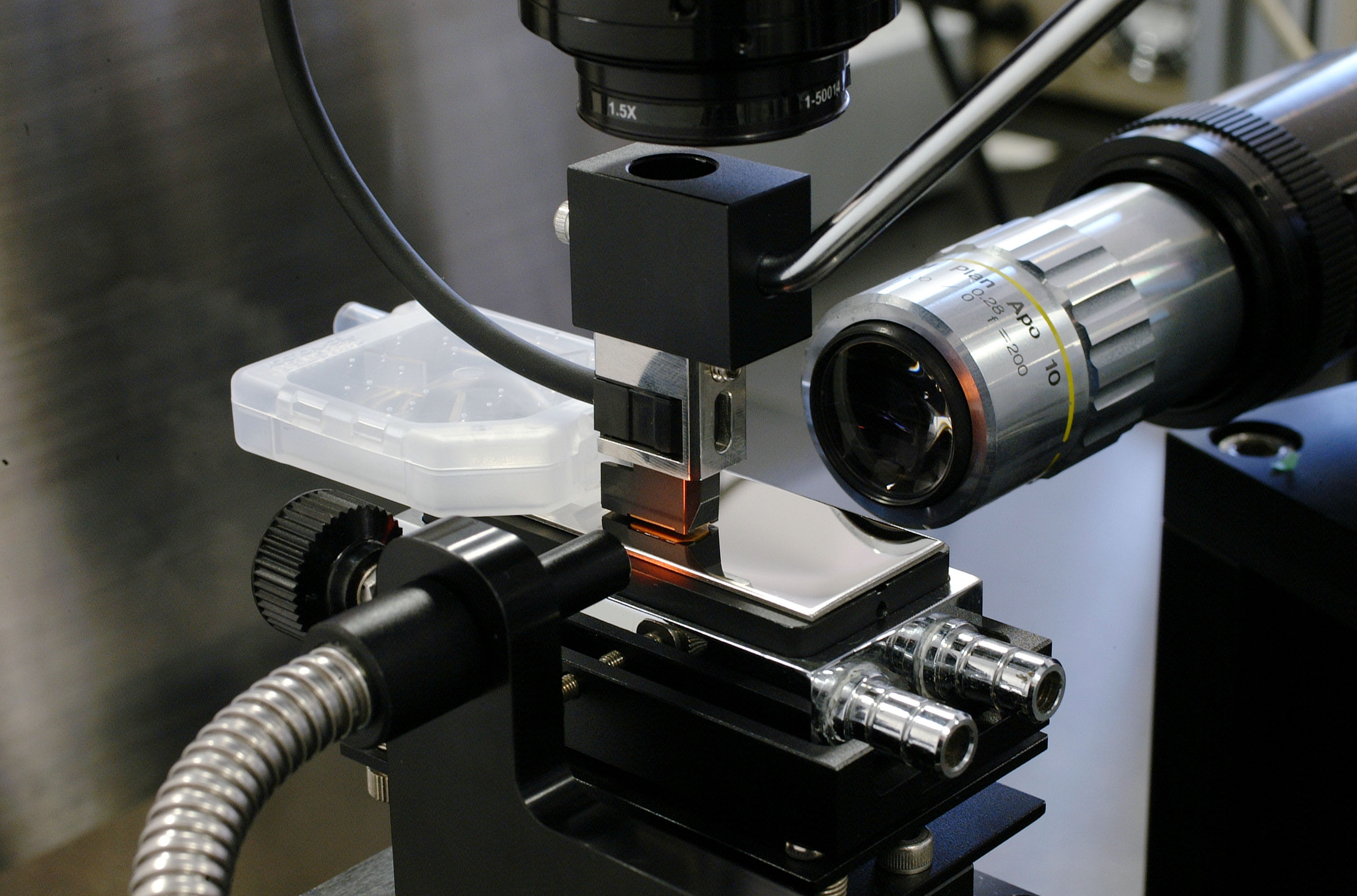

Top-view camera

This video shows how the top-view camera helps to deposition the droplets with a glass capillary with 5µm inner diameter with pinpoint accuracy onto measuring points of a circuit inside a ROM and of a read-write head of a hard disk.

The two videos below show that besides the pinpoint deposition of the droplets the top-view camera can also be used for the observation of the three-phase contact line of the droplets. Here, droplets are deposited inside 100µm wide cells of an OLED panel. As the height of the cells' walls does not allow direct measurements of the contact angle from the side, the top-view camera helps to evaluate the surface cleanliness by observing the spreading behavior of the droplets on the solid surface.

- Fast image capturing system with standard 400 fps at 640x480 resolution USB3.0 CMOS camera, max. 2700fps at 640x64 resolution

- Automatic recognition of drop deposition by FAMAS analysis software

- Top view camera allows for deposition of droplets with pinpoint accuracy and for observation of the spreading of micro-droplets

- The high magnification lens and a 12-fold zoom provide a field of view from approximately 75x56µm to 910x680µm

- Fine adjustable micro stage in x-, y- and z-axis for exact positioning

- Fast image capture system allows accurate measurements of even quick evaporating pico-liter droplets

- Droplet calibration standard bearing three sets of one full circle for calibration and three droplet silhouettes of 5º, 60º, and 108º for periodic inspection of measurement accuracy

Hardware

- Jacket-type sample stage for temperature measurements from +10 to +70℃

- Inkjet head system, using piezoelectric technology to generate droplets from about 8 to 60pL

- Miniaturized areas such as of silicon wafer, OLED panels, electronic components, printed circuit boards, etc.

- Very thin wire materials such as single fibers, hairs, filaments, etc.

- Defined locations on the surface of tiny samples

- Ink at very small droplet volume (emitted from an ink-jet head)

- Other or micro-structured areas where conventional methods and droplet volume are not applicable

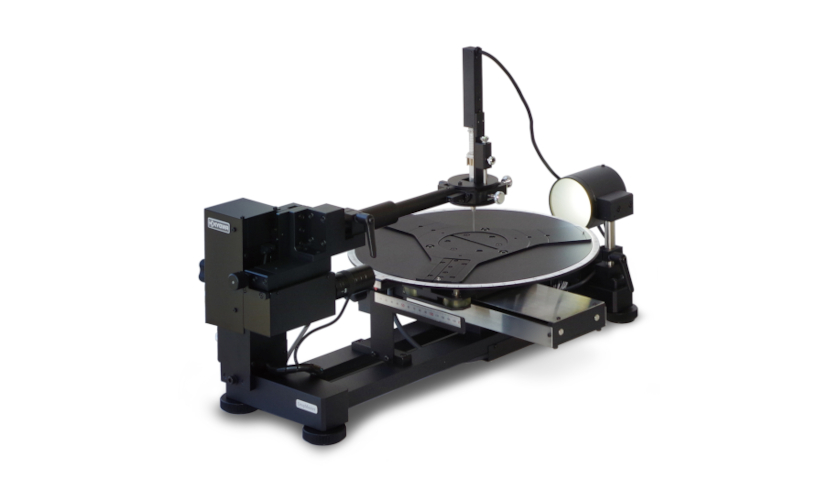

| MCA-4 | |

| Camera system |

USB3.0 CMOS camera with: 400fps at 640x480 pixels 500fps at 640x400 pixels 1000fps at 640x200 pixels 2700fps at 640x64 pixels |

| Optical system |

focus: manual focus with a 12-fold zoom lens field of view: 75x56μm to 910x680μm ±5% magnification: 5.3 to 64 times |

| Measuring methods | contact angle: sessile drop (static and dynamic) |

| Analysis methods |

contact angle: θ/2, tangent, curve fitting (ellipse, circle) surface free energy of solids: OWRK, Owens-Wendt, Kaelble-Uy, Kitazaki-Hata, Wu, acid-base, Zisman |

| Measuring range | contact angle: 0 to 180° |

| Resolution | contact angle: 0.01° |

| Accuracy1) | contact angle: 0.5° |

| Maximum sample surface area and height (WxDxH) | 50x25x5mm |

| Sample stage operation: X-axis Y-axis Z-axis |

manual 25mm 25mm 15mm |

| Dispenser operation: X-axis Y-axis Z-axis Droplet generation Air supply pressure |

three-dimensional manual manipulator 30mm 30mm 30mm + 10mm hydraulic micro-manipulator automatic 0.4 to 0.7 Mpa |

| Dimensions (WxDxH) of: Main instrument Rack for control boxes Installation area |

550x620x700mm 420x320x323mm 1000x650x720mm |

| Approximately weight of: Main instrument Control box |

50.0kg 15.0kg |

| Electric power: Voltage Frequency Power consumption |

AC100-240V 50/60 Hz 60W 125VA |

| Operating environment |

temperature: +10 to +35℃, humidity: 30-80%RH (non-condensing) positioned away from sources of electrical noise and vibration |

1) Accuracy is the repeatability in terms of standard deviation based on the manufacturer’s calibration standard