What is Peel Adhesion?

A pressure-sensitive adhesive (PSA) tape is used in various fields because it can be applied instantaneously with rather weak pressure and is easy to remove. Specifically, across multiple forefront industries, such as in the fabrication of liquid crystal panels, semiconductors, optical instruments, and solar batteries, and in medical treatment, the automobile industry, architecture, and IT, the unique capability of PSA is applied to the production process as well as constitutive parts in devices.

PSA tape is valued based on three basic elements: the so-called tack test, adhesion, and shear-holding power. In general, the peel test quantitatively measures adhesion forces at 90º and 180º angles in response to JIS Z0237:2009.

At a 180º angle, the peel test result is influenced by the thickness and degree of elasticity of the PSA tape. At a 90º angle, the result is less influenced by these characteristics of the tape and is more reliable and consistent for evaluating adhesion and cohesion. However, the test result is unsatisfactory at present due to the deviation from a 90º angle arising from the sagging and elongation of the tape.

Conventional Multi-angle Peel Test Method

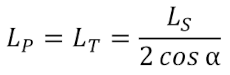

Peel testers for multi-angle measurements are already available. To maintain the peel angle constant, linear movement of a substrate and a tilted detector element is utilized by simply satisfying the geometrical condition, as shown in Fig. 1.

The following formula shows the peel angle:

The peel distance ![]() equals the tensile distance

equals the tensile distance![]() , but the sample stage travels horizontally from A to A’ indicated as

, but the sample stage travels horizontally from A to A’ indicated as ![]() .

.

The relational calculus is expressed as the following formula,

where Lp is the velocity of the stage movement.

Fig.1: Principle of conventional multi-angle peel test method

Flat Plate Cross Stage Peel Test Method

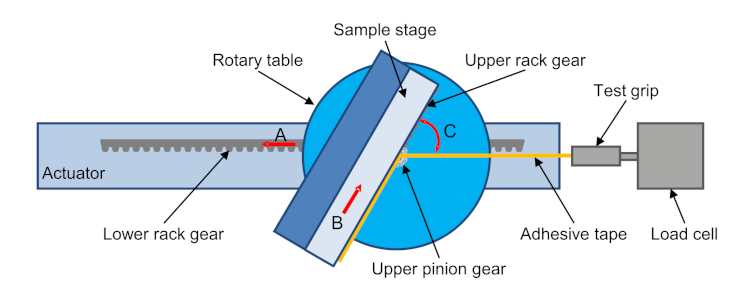

Kyowa Interface Science Co., Ltd. invented the Flat Plate Cross Stage Method.

The synchronized actuator mechanism is designed to evaluate the flat plate sliding at specified crossed angles with the pulling direction on a stage with high accuracy.

Refer to Fig.2, a flat cross stage shifts in the direction of A while a stage moves toward the direction of B at the same distance and speed.

Fig.2: Principle of the Kyowa'a Flat Plate Cross Stage peel test method