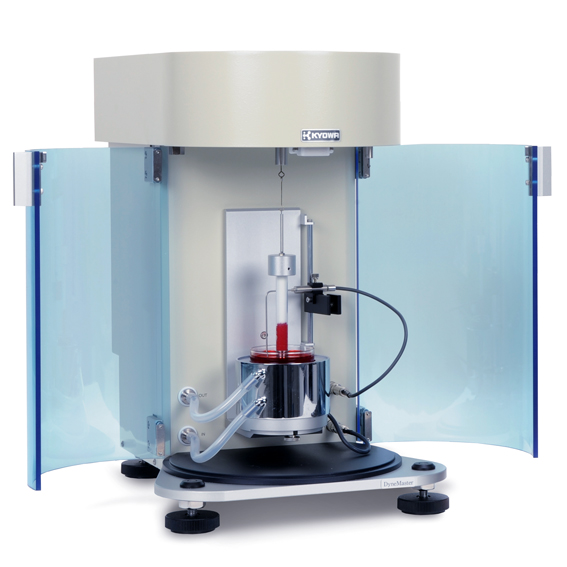

The DY-500 and DY-700 share the same body design and only differ by the integrated weighing system, with the DY-700 offering 10 times the readability of the DY-500. Both are fully automatic, high-precision, and easy-to-use surface tensiometers for reliable measurements of dynamic contact angle and powder contact angle, in addition to measurements of surface and interfacial tension, lamella length, liquid and solid density, sedimentation behavior, and evaporation rate.

Due to their accuracy and high versatility, both models are ideal for use in R&D as well as for reliable measurements for routine quality assurance.

High-quality components and the durable design combined with a video user manual integrated into the software guarantee user-friendly operation of the instrument and software.

Citations

Our devices are widely recognized as benchmark tools across various scientific and research fields.

This acknowledgment is solidified by their frequent citation in numerous scholarly publications.

We encourage you to explore the articles below, highlighting our technology's extensive use and impact.

Feel free to download and share them within your networks.

Product Promotion Video

DY-700

Explore the versatility of the Kyowa DY-700 surface tensiometer and its benefits in this video (7 minutes).

- "One-click" fully automated operation

- Jacket type sample stage with built-in stirrer function

- Built-in temperature sensor

- Connections to the sample chamber for inert gas

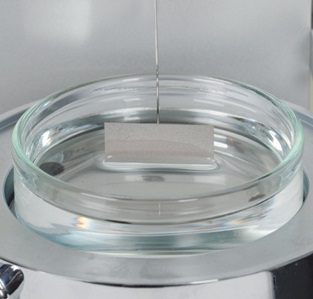

- Pre-wetting function to eliminate measurement errors caused by unsuccessful wetting of the Wilhelmy plate or du Noüy ring

- Easy parameter setup to adapt various measuring standards

- Video user manual for user-friendly operation

- Adjustable level of the body

- Calibration by an external weight for the DY-500 and by an internal calibration system for the DY-700

Hardware

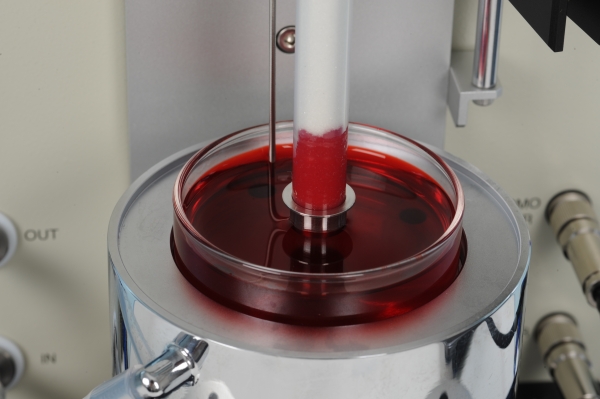

- Powder contact angle measurement kit

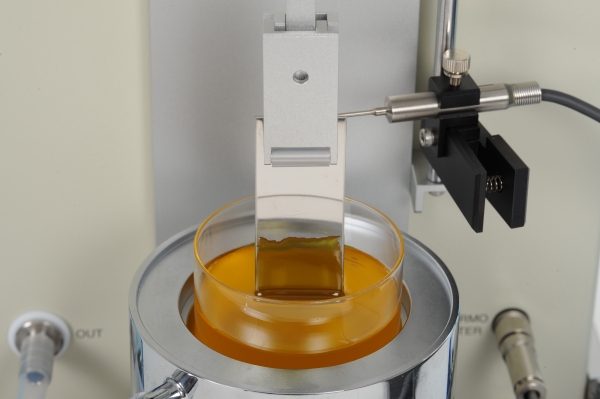

- Dynamic contact angle measurement kit

- Automatic CMC measurement kit

- Sedimentation behavior measurement kit

- Liquid & solid density measurement kits

- Heater-type sample stage for temperature measurements from ambient to +150 ℃

Software

- Dynalyzer software add-in [powder contact angle measurement]

- Dynalyzer software add-in [dynamic contact angle measurement]

- Surface tension: Paints, inks, additives for coating processes

- Interfacial tension: Transformer oil, emulsions, surfactant solutions

- Lamella length: Paint leveling, foaming stability of coatings and fire extinguishing agents

- Sedimentation behavior: Flocculants used in wastewater treatment, stability of suspensions, such as paints and pigmented inks

- Powder contact angle: Wetting properties of powders, inks, and paints

- Dynamic contact angle: Wetting and adhesion properties of coatings

| DY-500 | DY-700 | |

| Measuring methods |

surface tension (Wilhelmy plate and du Noüy ring) interfacial tension (Wilhelmy plate and du Noüy ring) lamella length (du Noüy ring) liquid & solid density 1) sedimentation behavior 1) powder contact angle (Washburn method) 1) dynamic contact angle 1) |

|

| Measuring range |

surface/interfacial tension: 1 to 1.000 mN/m powder contact angle: 0 to 90 ° dynamic contact angle: 0 to 180 ° liquid density: 0.001 to 3.3 g/cm3 solid density: 1 to 25 g/cm3 |

|

| Resolution |

surface/interfacial tension: 0.01 mN/m powder contact angle: 0.01 ° dynamic contact angle: 0.01 ° liquid density: 0.0001 g/cm3 solid density: 0.0001 g/cm3 |

|

| Accuracy2) |

surface/interfacial tension: 0.2 mN/m contact angle: 0.2 ° |

surface/interfacial tension: 0.02 mN/m contact angle: 0.02 ° |

| Calibration method | by an external calibration weight | by a built-in calibration system |

| Sample stage operation: Speed Stroke |

software controlled 0.002 to 50 mm/s 50 mm |

|

| External dimensions (WxDxH) |

295 x 415 x 425 mm |

|

| Approximately weight | 20.0 kg | 23.0 kg |

| Electric power: Voltage Frequency Power consumption |

AC 100-240 V 50/60 Hz 35 W 75 VA |

|

| Operating environment |

temperature: +10 to +35 ℃, humidity: 30 to 80 %RH (non-condensing) positioned away from sources of electrical noise and vibration |

|

1) Optional measuring probe is required

2) Accuracy is the repeatability in terms of standard deviation based on the manufacturer’s calibration weights