Evaluation of the cleanliness of the surface by contact angle measurements

Background

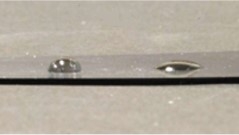

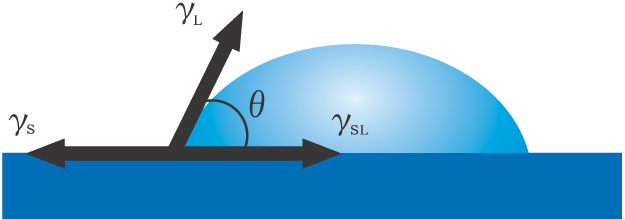

The contact angle measurement is very sensitive and affected by nanometer film thickness and can detect even slight changes in the surface. Therefore, it can be used as a measurement to directly investigate the affinity between liquid and solids, such as ink and the to-be-coated surface, and also an indirect measurement by determining changes in solid surfaces caused by contamination, cleaning process, surface modification treatment (corona or plasma discharge), etc. by comparing contact angles of distilled water (Fig. 1).

Figure 1 – Rubber substrate with one water droplet on an untreated area on the left and another on the plasma-treated area on the right

Problems to be solved

For instance, wafers and substrates must be thoroughly cleaned, or defects will occur in the following processes. Although it is possible to measure the residual oil content after cleaning by X-ray or infrared spectroscopic analysis, these devices require a reasonably skilled measurement technique, are large in scale, and are very expensive.

In contrast, a simple evaluation index of surface treatment and cleanliness using a contact angle meter is relatively easy to measure and relatively inexpensive, so it is a device that we would like to propose in terms of cost performance.

Measurements and results

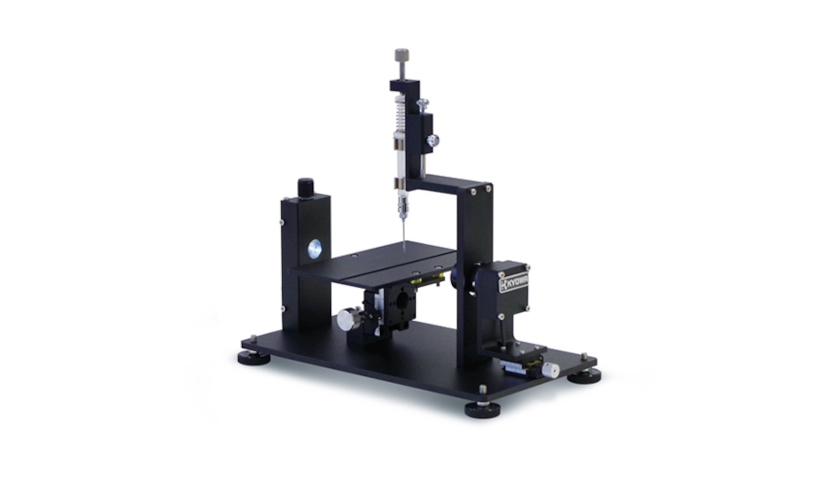

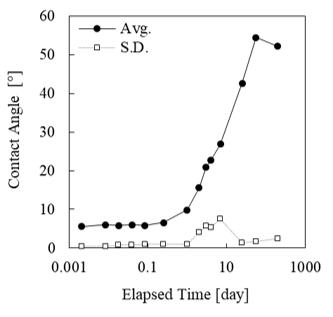

When testing, clean glass slides were left in the air (in a non-clean room) immediately after opening the package, and the contact angle was measured using the sessile drop method at each elapsed time (Fig. 2).

Figure 1 – Contact angle Θ

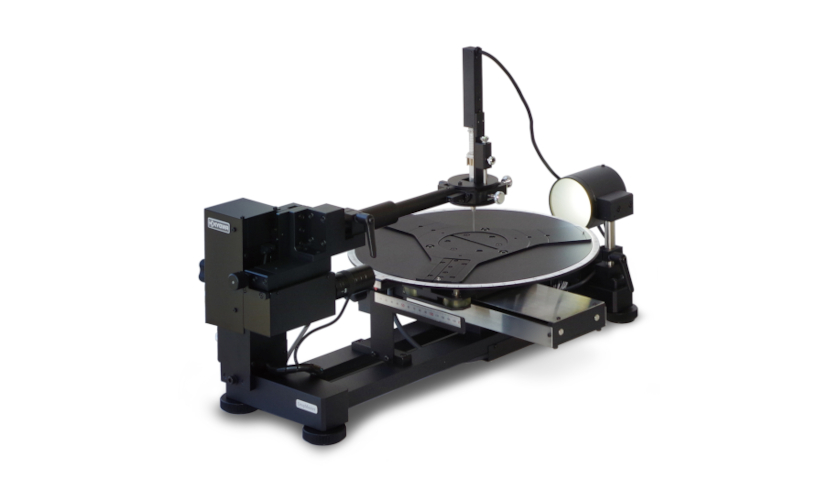

In a non-clean room, we used our contact angle meter model DM-500, a legacy instrument, under the following conditions:

| Liquid sample: | 0.5 µL of distilled water |

| Solid sample: | Unused glass slides from an unopened package |

| Room temperature: | 20-27℃ |

| Relative humidity: | 30-56% |

Figure 3 – Relation of atmospheric exposure time and the contact angle

Figure 3 – Relation of atmospheric exposure time and the contact angle

As a result, the contact angle value (Avg.), which was 5.6º immediately after opening the package, began to increase significantly after one day of exposure to air and became almost constant after two months (Fig. 3). On the other hand, the standard deviation (S.D.) increased during the period from 1 to 10 days and then decreased. This indicates that the contact angle measurement with water is helpful as a simple method to evaluate the surface condition of solids indirectly.

Conclusion

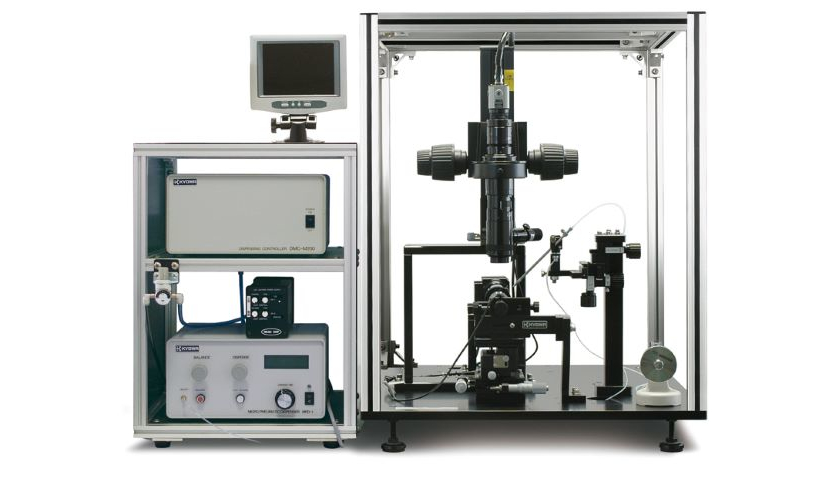

Our contact angle meter series is suitable for evaluating the cleanliness of the surface under actual usage conditions, ensuring the best reliability and product quality.

Related Products

Visit our Virtual Showroom

to learn more about our company's products