Functions and measurement routines

This page provides a brief overview of some functions and measuring routines of our Triboster TSf-503.

For more detailed information, please Contact Us or your local agent. "Where To Buy"

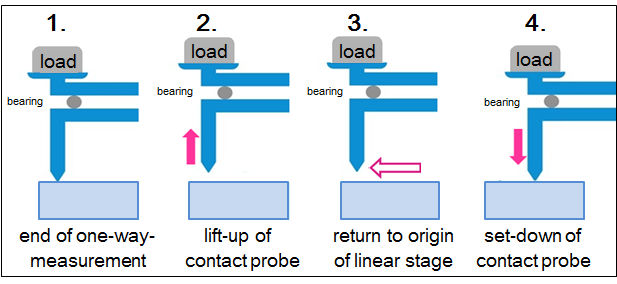

Automatic contact probe lift-up function

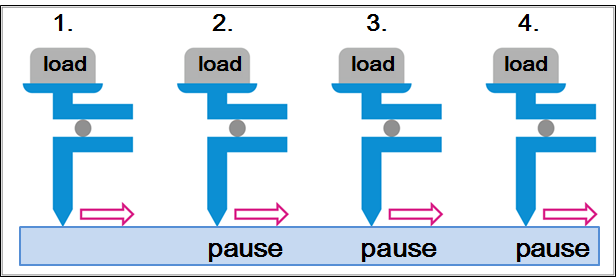

Continuous static friction

Used for measurements focusing on static friction, generally measured with slow speeds up to 1.0mm/s.

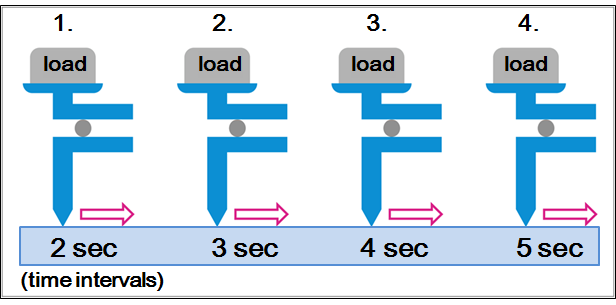

Time-interval dependency

Used to evaluate the influence of adhesion between the sample and the contact probe or attached specimen.