Evaluation of the adhesive strength between the electrode slurry coating and the metal foil used for electrode materials (2)

Background

The existing oxide film on the aluminum foils used as electrode material increases the electrical resistance, negatively affecting the electron transfer.

A conductive carbon slurry coating on the aluminum foil's surface helps to reduce this resistance.

Finding formulations to overcome the challenging adhesion conditions at the aluminum-slurry interface is critical to avoiding unwanted separations of the coating from aluminum foil, which are the main causes of short circuits and battery damage.

Problems to be solved

Although improving the adhesion is an issue, the bonding strength between the aluminum foil and the conductive carbon coating film is still meager. Therefore, using a conventional tensile tester with the 180º peel test may be challenging or impossible.

In addition, the coating film may immediately separate from the aluminum foil when bent to 180º due to the backing’s stiffness of the adhesive tape used to peel off the thin film.

Measurements and results

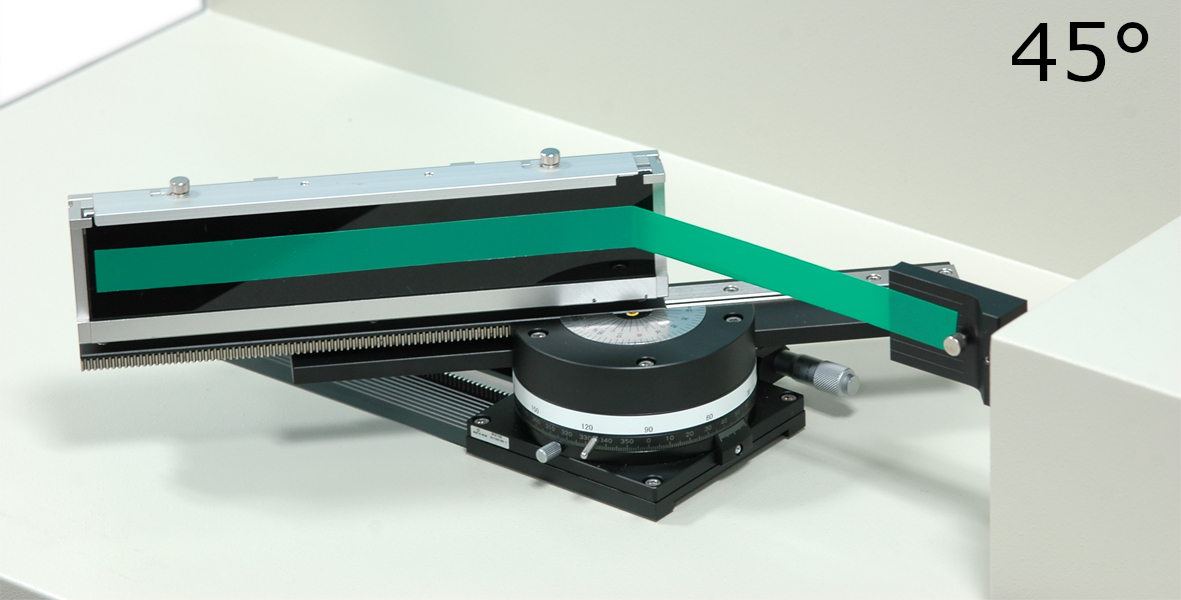

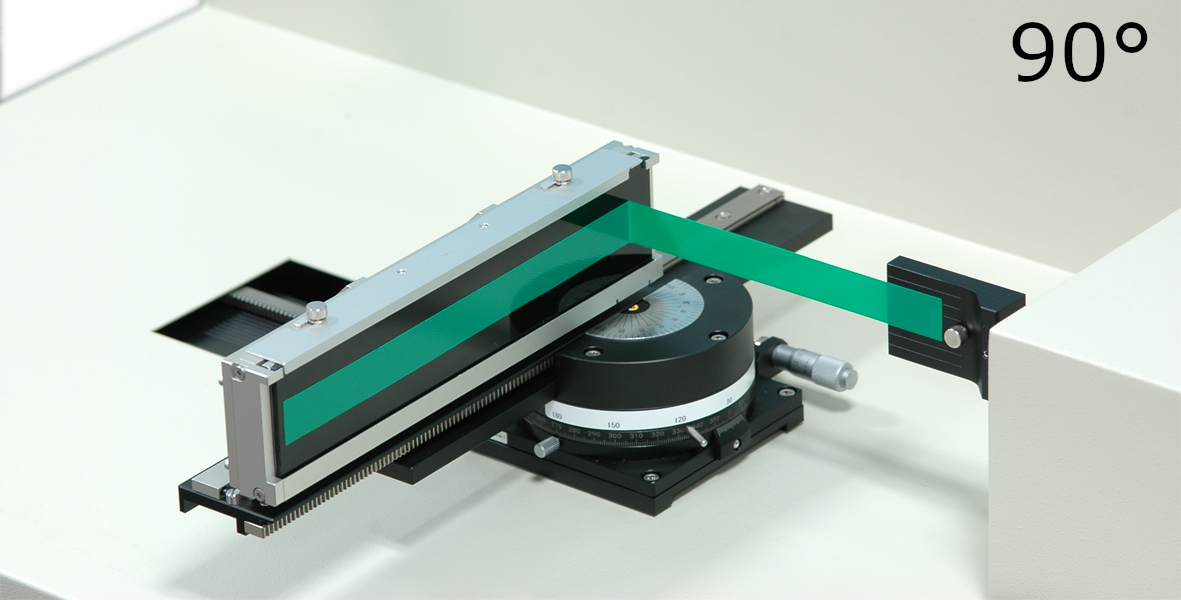

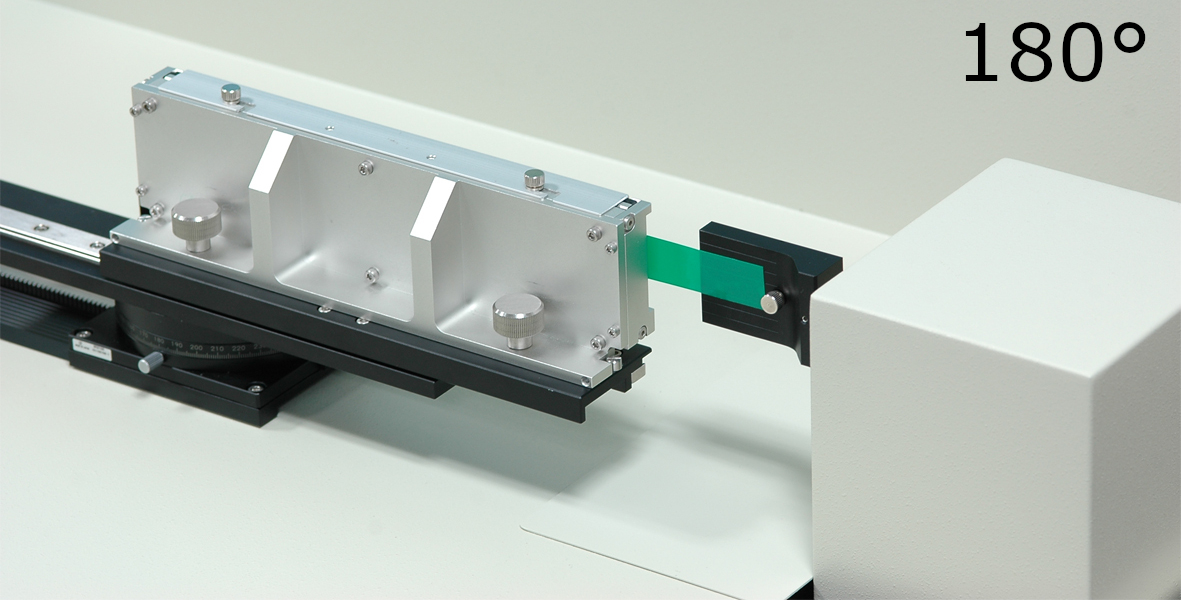

The Kyowa Versatile Peel Analyzer model VPA-3 performed the measurements using a standard full-scale 5N load cell. The peel angles for samples A and B were 45º, 90º, and 180º, respectively.

Figure 1 – Images of the stage in different positions (not actual samples)

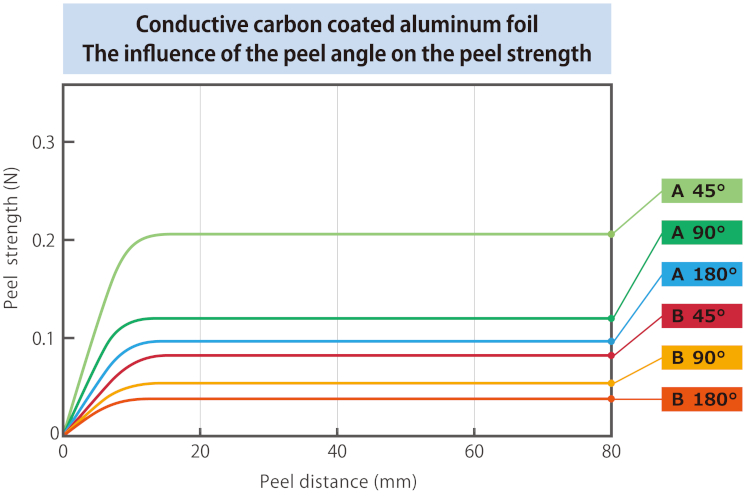

As a result, the smaller the peeling angle, the more significant the difference between samples A and B. In particular, the 45º peel angle shows a remarkable difference in the peel force between both samples.

Figure 2 – Comparison chart of the test results

Conclusion

Lower peel angles reduce the influence of the rigidity of the adhesive tape’s backing on the peel force. The difference between the samples becomes more apparent when the forces are detected further toward the shearing direction of the coating film.

Related Products

Visit our Virtual Showroom

to learn more about our company's products