Evaluation of the adhesive strength between the electrode slurry coating and the metal foil used for electrode materials (1)

Background

Besides the adhesion between the current collector foil and the electrode material made of active material, conductive carbon, and binder, the binder distribution in the graphite anode plays a significant role in determining lithium-ion batteries’ unique properties, such as the long cycle life and high energy density.

From the viewpoint of conductive performance, the binder is an impurity. To achieve optimum adhesion, uniformly dispersing the binder in the least amount possible while holding and maintaining a solid connection between all particles is required.

Problems to be solved

To evaluate the adhesive force between the electrode slurry's coating layer and the metal foil, we performed the 180º peel test using cellophane tape to peel off the electrode coating. Still, the bonding strength was minuscule, showing no significant difference between the samples with different coating thicknesses.

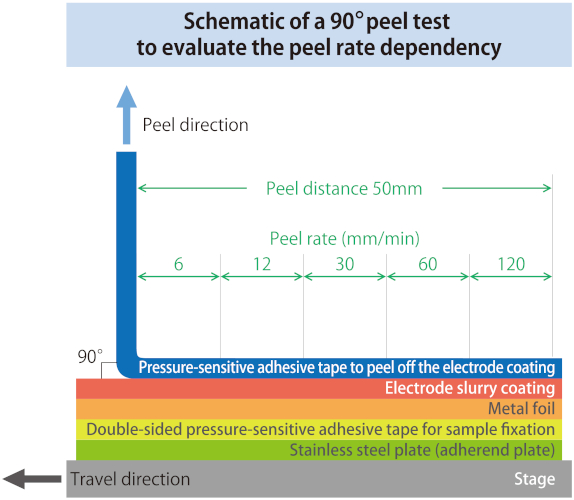

Then, we focused our attention on the possible dependence of the peel force on the peel rate. To address the differences in the coating layer's film thickness, we chose a peel angle of 90º to minimize the influence on the measurement results for better comparison.

Measurements and results

The Kyowa Versatile Peel Analyzer model VPA-2 carried out the peel rate dependence measurements in one peeling step by changing the peel rate in five stages of 6mm, 12mm, 30mm, 60mm, and 120mm/min, respectively, for every 10mm peeling.

Figure 1 – Schematic of the peel test

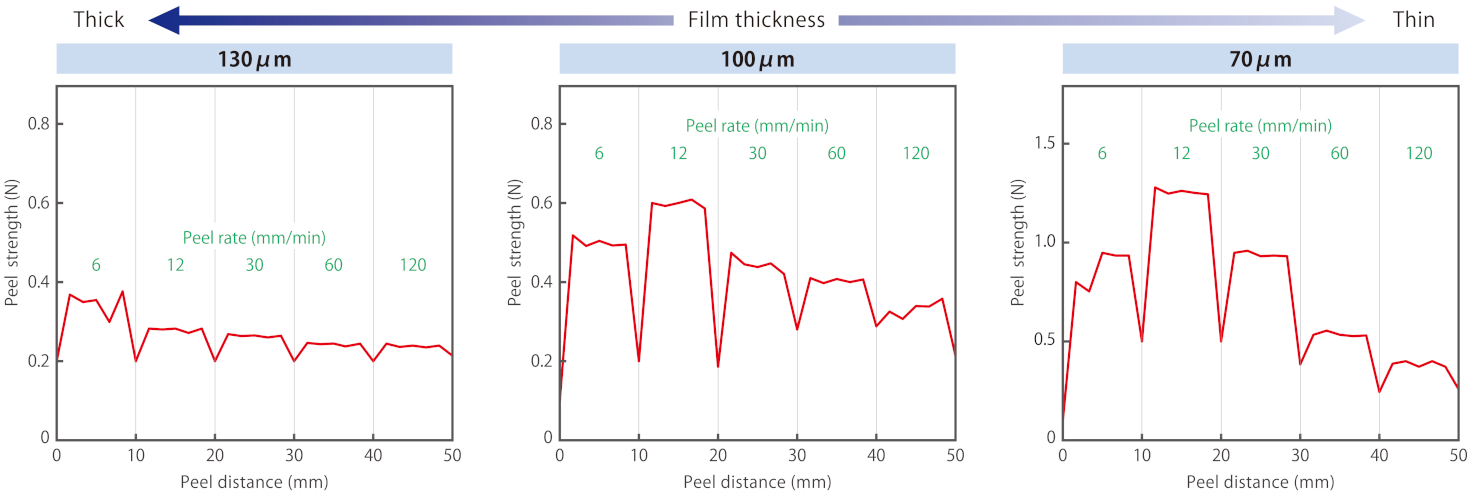

The adhesive strength tends to be strong in the low-speed range regardless of the film thickness. When comparing film thicknesses, the thinner the coating layer, the stronger the adhesion in the low-speed range. The difference between the low and high-speed ranges is remarkable.

The thicker the coating layer, the weaker the adhesion to the metal foil. The reason may be that the thickening of the film leads to cohesive failure.

Figure 2 – Results of the different test runs

Related Products

Visit our Virtual Showroom

to learn more about our company's products