Evaluation methods of adhesive strengths for adhesive layers and functional thin films using a horizontal peel tester

Introduction

Pressure adhesive tapes and adhesive sheets represented by cellophane tapes and protective films that are familiar as daily necessities are indispensable as constituent materials and in the production process in advanced technology fields such as information and communication technology and semiconductors.

They play an essential role as a suitable material. Requirements for the adhesive strength are not like the stronger, the better, but it must be appropriate for a specific task. For example, in the production process, it is once attached as a protective film to protect the product’s surface but will be peeled off when it has finished its role. Here, it is required to easily peel off without leaving adhesive residue while maintaining the minimum adhesive strength for fulfilling the function. In addition, there are various ways to peel it off. In other words, the characteristics of the product application.

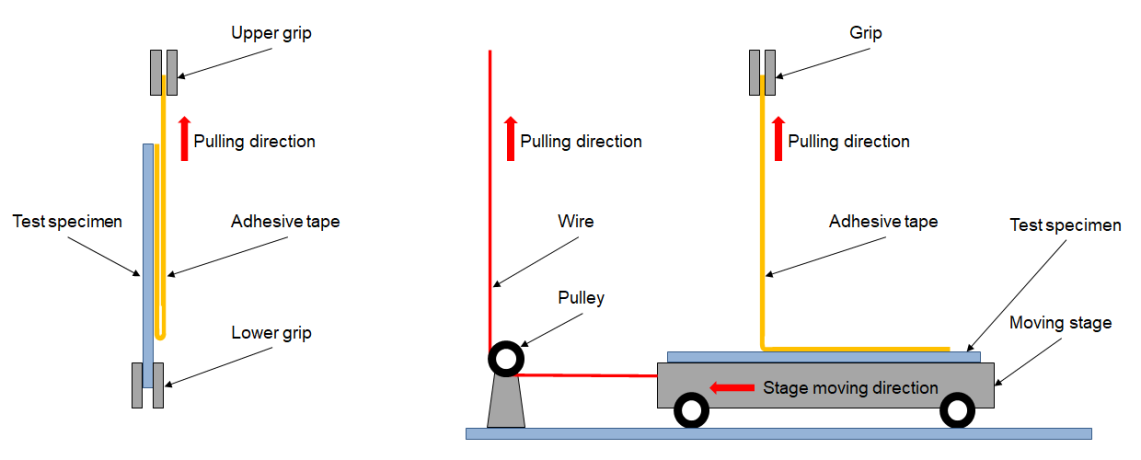

Besides the adhesive or peel force, the peel angle and peel rate vary depending on the characteristics of product applications, and they always need to be optimized. Traditionally, the use of universal testing machines (UTM) in the product evaluation of such adhesive tapes and sheets is widespread. Among them, the dual-column type has a center of gravity compared to the single-column type, which is an ideal structure for measuring strong force. Therefore, it is suitable for measuring high loads such as metal materials.

However, in the case where optimization of peel adhesion is required, as described above, it is necessary to measure the adhesive force in a relatively light load range with high accuracy. Therefore, the horizontal tensile tester is suitable for the following reasons:

1. Canceling the grips’ weights, using the load cell’s full-scale capacity is possible even with a low-capacity load cell.

2. High-speed peel tests are possible due to the less affection for gravity than vertical UTM.

Conventional adhesive strength test methods

180º peel and 90º peel test

As evaluation items for adhesive tapes and sheets, “tack”, “adhesive strength”, and “holding strength”, which are the three essential elements, are known. The peel test is the primary measurement method that numerically captures “adhesive strength”. The procedure for measuring the peel strength of adhesive tape is, among others, specified by JIS Z 0237: 2009 Testing methods of pressure-sensitive adhesive tapes and sheets, based on ISO 29862: 2007 Self-adhesive tapes - Determination of peel adhesion properties.

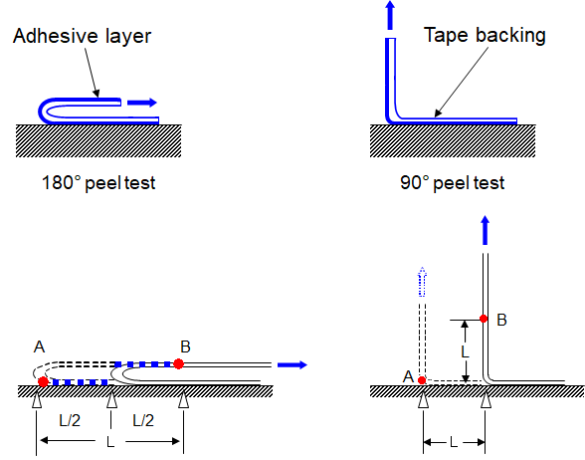

This national test standard describes the 180º peel test and the 90º peel test (Fig. 1). An auxiliary jig attached to a vertical tensile tester allows to carry out the 90º peel test. Still, the peeling process is unstable due to its design, resulting in unreliable measurement results while maintaining the 90º angle. Therefore, instead of becoming an established daily test method, using data from the 180º peel test is typical for evaluation.

Figure 1 – Schematics of the 180º peel test on the left and the 90º peel test on the right

However, the results at 180º are easily affected by the backing’s thickness and rigidity of the adhesive tape due to the large angle at which it is bent. The pull rate or test speed is specified as 5.0mm/s ±0.2mm/s, whereas the old standard required 300mm/min ±30mm/min.

Pull rate and peel rate

Although it is a general 180º peel test method, some more clarification is necessary. Figure 2 illustrates an adhesive tape’s 180º and 90º peel test. In the evaluation of adhesive and peel strength, of particular importance but often overlooked is the relationship between the pull rate and the peel rate at 180º and 90º.

Figure 2 – Comparison of the peel rate between the 180º peel and the 90º peel

Pulling an adhesive tape from point A to point B with a 180º peel test, the pulling distance is L, whereas the actual peel distance is only L/2. On the contrary, in a 90º peel, if the adhesive tape is pulled from point A to point B, the pulling distance L and the peel distance are identical.

・180º peel test: pull rate ≠ peel rate

・ 90º peel test: pull rate = peel rate

Since the 180º peel maintains the peel angle without moving the test plate in synchronization with the tape’s peeling, the peel rate becomes half the pull rate. As the pressure-sensitive adhesive is a viscoelastic material, peel strengths significantly change depending on the peel rate. Consequentially, comparing measurement results of 180º and 90º peel tests leads to false assumptions and erroneous conclusions.

Although JIS Z 0237 stipulates the test speed of 5.0mm/s ±0.2 mm/s, there may be times when you want to evaluate the tapes at 180º at the actual peel rate. In such a case, the test speed must be twice as fast as the mentioned rate.

T-peel test

The T-peel test is a standard method for evaluating adhesive tapes and sheets. The JIS standard “JIS K 6854: Determination of peel strength of bonded assemblies”, based on ISO 8510-1, Adhesives−Peel test for a flexible-bonded-to−rigid test specimen assembly, specifies the 90º, 180º, and T-peel test methods under defined conditions.

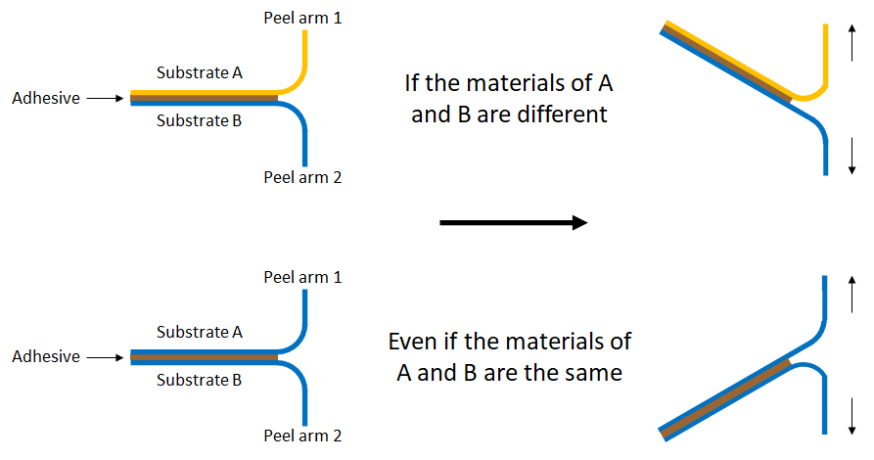

For both 90º and 180º peel tests, adhesive tapes are attached to test plates and pulled at either 90ºor 180º angle. The T-peel test is a test method performed upon two bonded flexible substrates. The separated ends, known as peel arms, will be clamped and placed into the test grips of a vertical tensile tester, with the two peel arms forming a 180º angle relative to one another. So the setup looks like a “T” shape, where one peel arm sticks up, the other sticks down, and the unpeeled area sticks out horizontally.

The material and thickness of substrates A and B to be bonded are often different, and due to the difference in material strength, the unpeeled area leans toward the lower strength side. As a result, even symmetrically bonded thin and flexible T-peel specimens can be subject to significant gravitational loading and turning to either side during peel-off when tested on vertical travel machines.

Figure 3 – Schematics of the T-peel test

In the T-peel test, the forces on the peel arms and substrates will dictate the actual peel angle, resulting in a peel rate that will differ from the pull rate.

Trends in multi-angle peel tests

Research on multi-angle peel tests

In Japan, due to the influence of JIS, no tensile tester could perform peel tests other than 180º peel, 90º peel, and T-type peel. However, with the increasingly widespread use of pressure-sensitive adhesive tapes and adhesive sheets, the variations of peel angle and rate increased with the number of product applications. It was impossible to measure under the actual conditions of use because of the lack of appropriate test equipment.

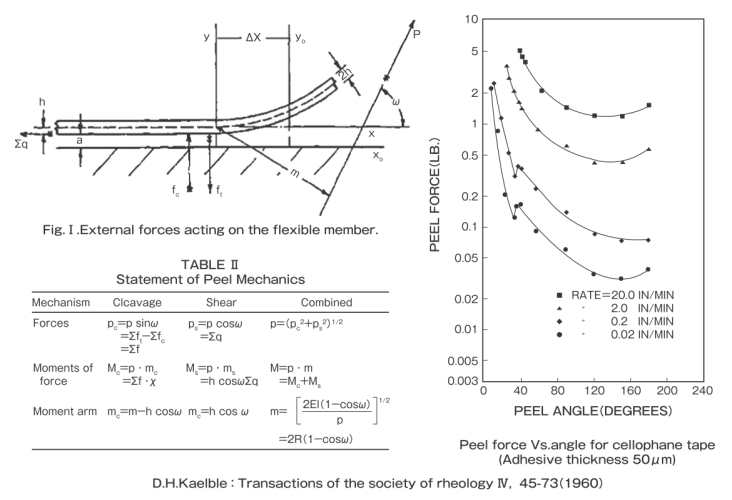

Overseas though, scientists have been engaged in research on multi-angle peeling tests for more than half a century. In 1960, D. H. Kaelble reported on the relationship between peel angle and peel strength based on the strength of materials. For example, the graph in figure 4 shows the peel angle dependence of cellophane tape.

Figure 4 – Schematics of the T-peel test

According to this, the peel strength becomes the minimum when the peel angle is between 120 to 160º and tends to become stronger as the peel angle becomes smaller. D. H. Kaelble uses a theoretical formula to describe the relationship between the peel angle and the peel strength.

Conventional multi-angle peel tester

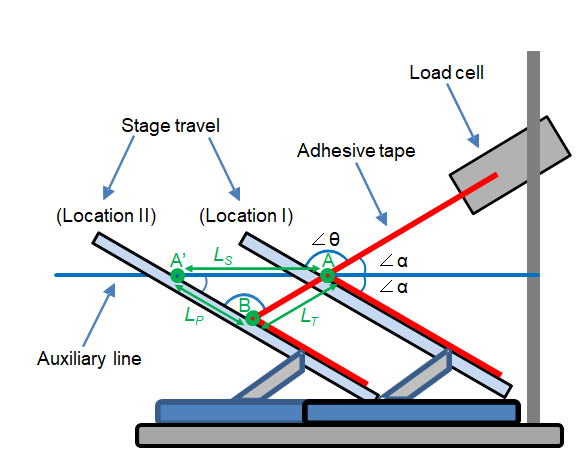

Figure 5 shows the measurement principle of Chem Instruments equipment that meets the needs of multi-angle peel tests in the United States. With this mechanism, it is possible to perform peel tests that maintain the set peel angle only by linear movement of the stage and satisfying the geometrical conditions without using a jig. The auxiliary line in Figure 5 does not exist but helps understand the measurement principle better.

Figure 5 – Schematics of the T-peel test

The sample stage and the load cell will be set at an angle α to the auxiliary line, using the following quotation:

𝛼 = 90º−𝜃/2

While moving the stage in the direction of the auxiliary line at a certain speed, the peel front moves from point A to point B, whereas the peel angle θ remains unchanged. Since the stage moves parallel from the peel front A at stage position I to the peel front B at stage position II, the angles at both points are identical. For example, the desired 90º peel angle becomes possible by setting the angle of the stage and the load cell to 45º.

On the other hand, when the peel distance is AB, the stage travel distance is AA’. Therefore, instead of an equal peel rate VP and test speed VS, the relationship becomes:

𝑉𝑃 = 𝑉𝑆 / 2cos 𝛼

Consequently, to evaluate the peel angle dependence, it is necessary to adjust the peel rate for each peel angle using the formula mentioned above.

Also, measurements of low peel angles would require pulling the load cell upward, so the device allows for measurement of peel angles in the range between 90º and 180º.

Horizontal tensile tester VPA series

Principle of the flat plate cross-stage method

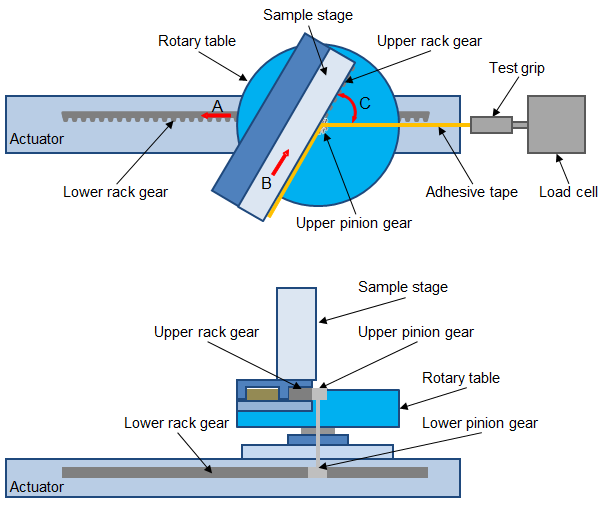

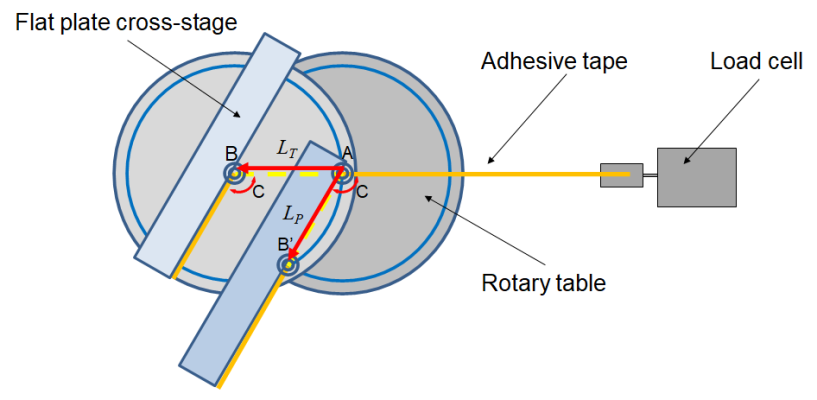

Figure 6 shows the unique mechanism of our flat plat cross-stage, Japan Patent No.: 4717156 (April 08, 2012), U.S. Patent No.: 8,813,553 (April 26, 2014)) for multi-angle peel tests.

Figure 6 – Schematics of the operation mechanism of the flat plate cross-stage method

The peel angle C is set with the sample stage on top of the rotary table, which sits on the moving stage. When the moving stage travels in direction A, the sample stage on the rotary table moves synchronized in direction B with the help of internal rack and pinion gear assembly. This mechanism maintains the peel angle C by moving the rotary table in direction A and the slide stage in direction B at an equal distance.

Figure 7 – Schematic of the movement of the rotary stage and sample stage (flat plate cross-stage)

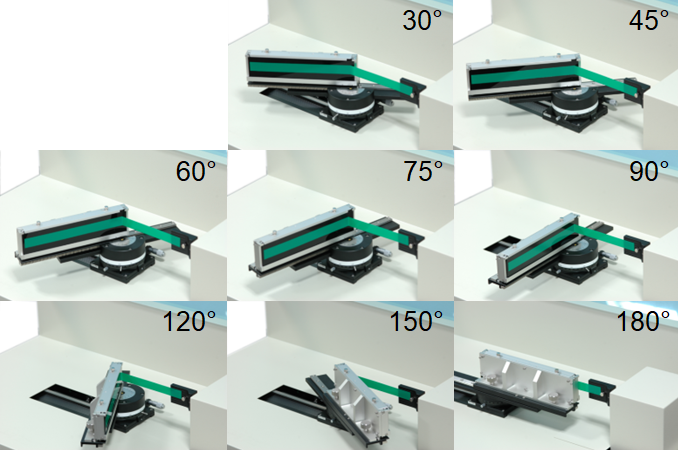

The horizontal versatile peel analyzer VPA series is the only device that enables peel tests at any peel angle from 0 to 180º (see image 1) while assuring peel rate = test speed (pull rate).

Image 1 – Sample stage positions at freely chosen angles

Overview of the VPA series

The VPA series has two models with different housing sizes. The large VPA-H200 has a sample size and peel distance of 200mm, and a maximum peel speed of 30,000mm/min for high-speed peel tests, whereas the small VPA-H100 offers a sample size and peel distance of 100mm, with a maximum peel speed of 12,000mm/min. But even this is considerably fast compared to existing models, and the installation space is small.

Image 2 – External appearance of the horizontal versatile peel analyzer VPA-H200F model

In addition, six load cells ranging from 0.1N to 100N are available and can easily be exchanged depending on the anticipated peel strength range. Furthermore, optional heating and cooling stages support measurements of various temperature environments. Finally, since the test conditions and sample size of the tensile test vary from customer to customer, we offer custom-made solutions to accommodate almost any of the customers’ needs.

Features of the VPA series

1. Measurement of the peel angle dependence

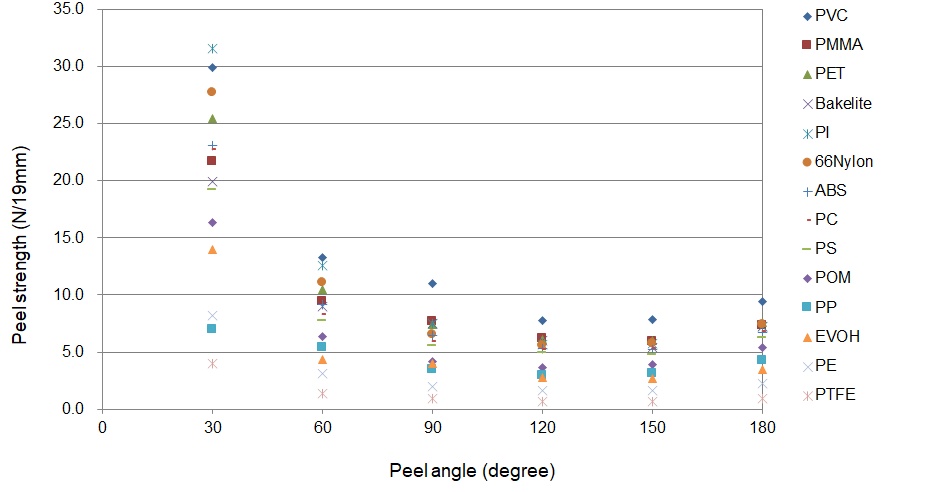

The VPA series has three significant features. First and foremost, with the help of the rotary table, the peel angle can be swiftly adjusted from 0 to 180º without using jigs or tools. This function allows easy and correct evaluation of the peel angle dependence. For example, figure 7 illustrates the peel angle dependence of a polyester adhesive tape on various polymer substrates. Here, too, the peel strength has its lowest value at around 120º and tends to increase as the peel angle becomes smaller. That is because the smaller the peeling angle, the more force acts in the shearing direction of the adhesive layer.

Figure 8 – Peel strength dependence on peel angles of various polymer adherends/polyester adhesive tape combinations

The phenomenon to reduce the peel angle and amplifying the apparent peel strength allows measurement of samples with weak adhesive force, which were once considered impossible to measure as they would easily separate from their backing when bent to 180º or 90º.

2. Measurement of the peel rate dependence

The second feature of the VPA series is that it can perform peel tests at extremely high speed for a desktop tensile tester. According to JIS Z 0237, the standard for measuring adhesive samples, the peel rate is 5.0mm/s±0.2mm/s (the old standard is 300mm/min±30mm/min).

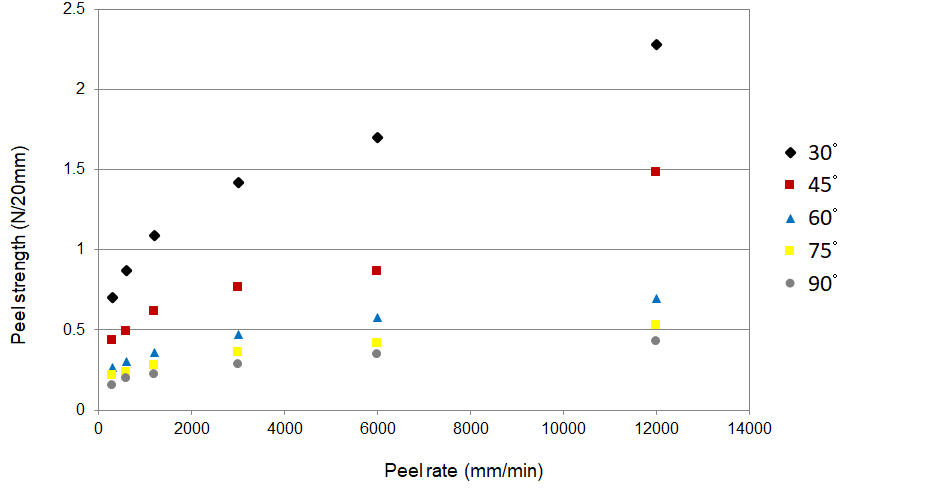

However, as mentioned above, the peel conditions vary from application to application. Therefore, it is hard to say that the test results based on JIS also reflect the peel strength in the actual use environment in terms of peeling rate. Figure 8 shows the peel angle and peel rate dependence between a label paper and its release paper.

At the old JIS standard peel rate of around 300mm/min, there is almost no difference in strength between angles at higher peel angles. On the other hand, as the peel rate increases, the peel strength also increases, and the difference in the adhesive force between peel angles becomes clear. Increasing the peel rate amplifies the apparent peel strength due to the influence of the viscoelastic behavior of the adhesive layer.

Figure 9 – Peel strength dependence of label and release paper on the peel angle and peel rate

With high-speed peel tests, it is possible to reproduce the peel speed in the actual use environment. Furthermore, once considered impossible, measurement of extremely weak adhesive bond substrates becomes possible using the viscoelastic behavior.

Widening the range of peel angle and rate conditions without being bound by JIS conditions effectively widens the scope of analysis.

3. Observation of the peel behavior

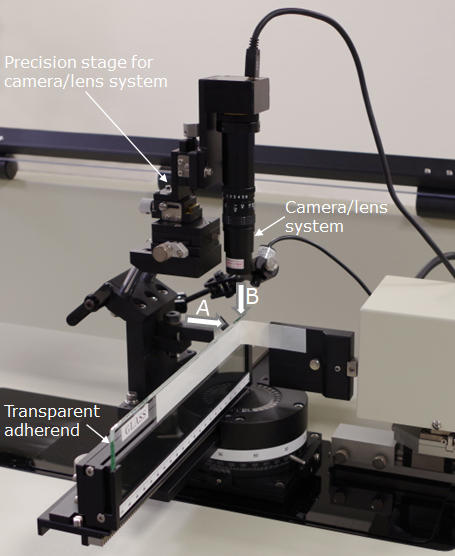

With the help of an installed camera-lens assembly on top of the flat plate cross-stage, which can be purchased optionally, tracking the actual peel process in synchronization with the stage operation delivers vital information on adhesives characteristics.

That makes it possible to observe the dynamic peel behavior during the adhesive tape’s peel-off from the adherend (see photo 3). For example, it is possible to validate the stringiness of the adhesive layer and consider the chemical or physical effects of the support and the adhesive.

Image 3 – Installed camera-lens assembly on top of the flat plate cross-stage

From the direction of arrow A in image 3, the peel behavior observation at the adhesive layer interface takes place from the rear surface of the transparent substrate via the prism. From the direction of arrow B, it takes place from the top.

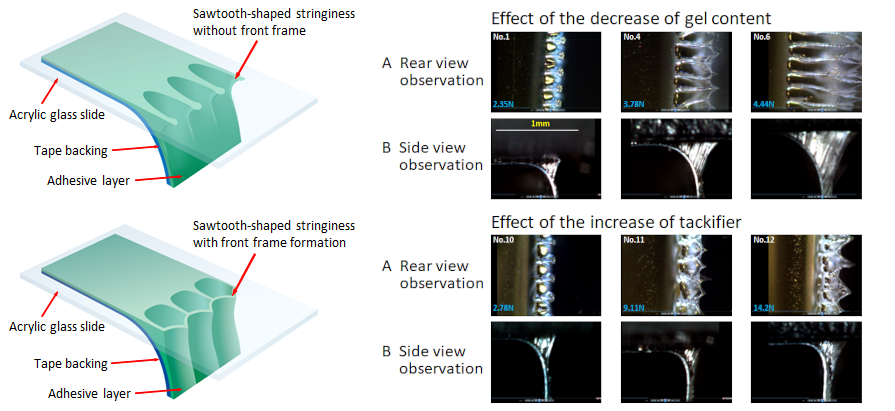

Image 4 shows the observation of the formation of sawtooth-shaped stringiness of an acrylic adhesive during 90º peelings. The performance modeling in modern product development requires more detailed information than just peel, tack, and shear properties.

Image 4 – Observation of the effect of cross-linking agents and tackifiers on the stringiness of an acrylic pressure-sensitive adhesive

The validation of fibrillation during the debonding process of adhesives delivers vital information on the effects of cross-linking agents on the gel fraction and tackifiers on the adhesive layer’s state.

Conclusion

The VPA series of horizontal peel testers enables measurement of conditions close to the actual usage environment due to the free peel angle and high-speed peel function, and also allows measurement of ultra-light peel samples, which was challenging to measure in the past.

For peel behavior observations, the practical peel rate range is up to 300mm/min with our standard camera systems. Custom-made solutions provide observations at even higher peel rates.

Related Products

Visit our Virtual Showroom

to learn more about our company's products