Evaluation of the peel ability between the carbon fiber prepreg sheet and the release paper

Background

Carbon fiber prepreg is a sheet-like material in which carbon fiber is impregnated with resin. It is used in a wide range of fields as an alternative to metal because it is lightweight, strong, and rigid. In addition, very high safety requirements must be met to manufacture aircraft fuselages and main wings.

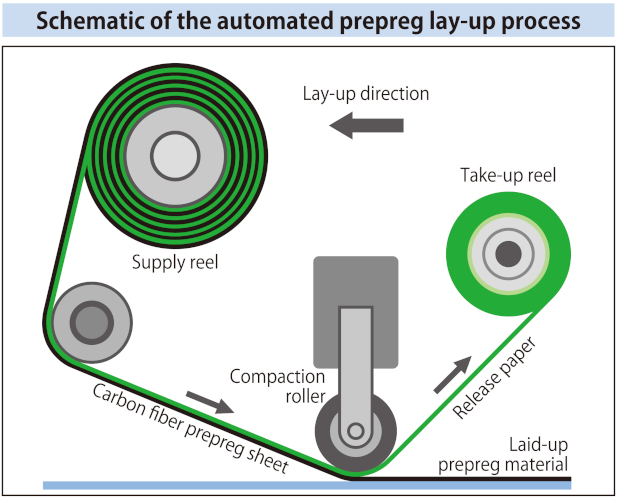

The prepreg laminate is formed by an automatic device equipped with a prepreg laminate head. The head peels off the release paper from the prepreg's surface, laminates the carbon sheet, and winds the release paper onto the take-up reel. Furthermore, the laminate head performs these three processes simultaneously. The easy-peel property is essential in the smooth operation of the prepreg lamination process. Patents report peel strengths of 0.7 to 3.0N/25mm.

Figure 1 – Schematic of the prepreg lay-up process

Furthermore, if the peel strength is too low, the prepreg and the release paper will peel off before use, and if the peel strength is too high, the silicone will adhere to the prepreg, causing laminate failure. Therefore, it is necessary to always manage to the optimum state.

Problems to be solved

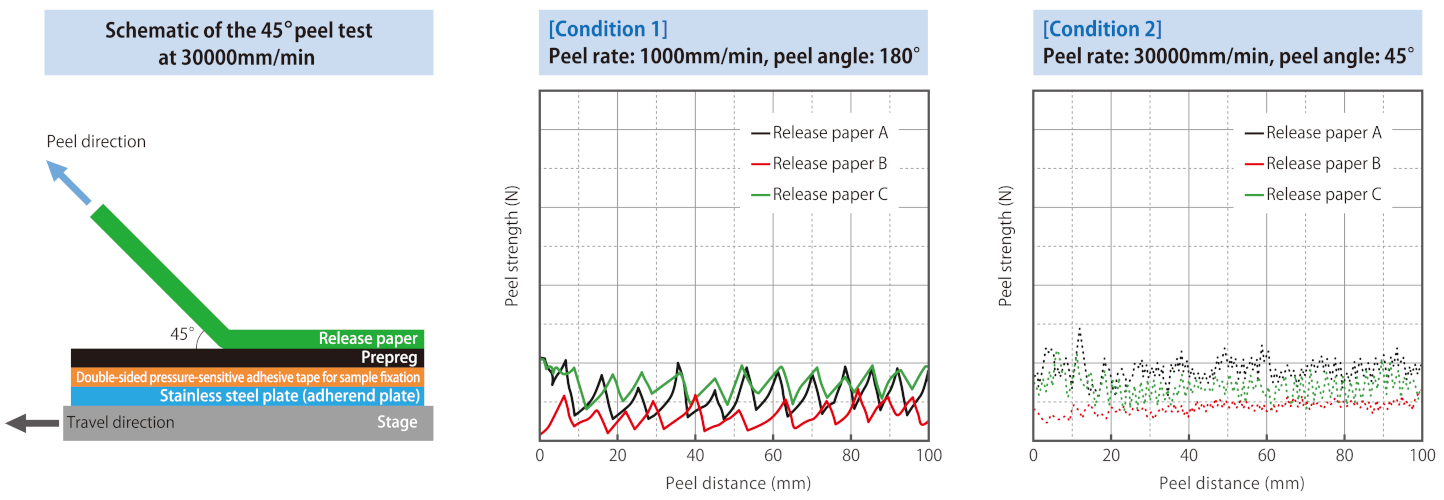

The peel properties of three types of release papers, A, B, and C, were evaluated, but the evaluation results and the peel strength in the laminating device were different. Since the laminate head operates at a 30 to 60m/min speed, we would like to evaluate the peel rate and peel angle under operating conditions.

Conventional testing machines' restricted peel rate of a maximum of 1.000mm/min and the lack of adjustable peel angles make them inappropriate for evaluating the peel properties under normal conditions of use.

Measurements and results

We used our Versatile Peel Analyzer model VPA-3 under the following conditions:

| Condition 1: |

Peel rate: 1,000mm/min Peel angle: 180º |

| Condition 2: |

Peel rate: 30,000mm/min Peel angle: 45º |

The results showed that the peel strength of condition 1, similar to conventional measurement conditions, was higher in C > A > B. Still, the peel strength order of condition 2, set under almost the same conditions as the prepreg laminating device, was A > C > B and matched the peel strength ranking of the laminating apparatus.

Figure 2 – Schematic of the 45º peel test and comparison charts of the test results

Conclusion

Our VPA-3 is suitable for evaluating peel strengths under actual usage conditions to ensure the best reliability and product quality.

Related Products

Visit our Virtual Showroom

to learn more about our company's products