Adhesion between the green sheet of the multilayer ceramic capacitor and the carrier film

Background

The demand for multilayer ceramic capacitors is expanding as mobile electronic devices such as smartphones and tablets become smaller and thinner and have larger capacities. In the manufacturing process of multilayer ceramic capacitors, the green sheet and the carrier film need appropriate peeling properties to avoid residue on the carrier film when peeled.

However, if the peeling property is too good, the green sheet may separate from the carrier film, or cracks occur during winding. Therefore, optimizing green sheet properties and evaluating the most appropriate adhesive strength is critical to avoid such problems.

Our Versatile Peel Analyzer is a reliable tool that aids in finding the best combination by simulating specific test conditions similar to the stresses the samples undergo during operation. It provides scientists with detailed data and test results for their research, keeping them well-informed.

Problems to be solved

The adhesive force between the green sheet and the carrier film is minuscule, whereas conventional universal testing machines reach their limits when detecting these tiny peel strengths. Furthermore, peel tests may even be impossible to perform.

Measurements and results

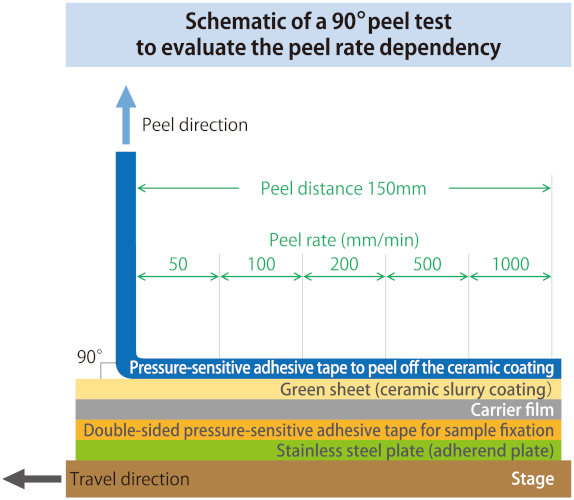

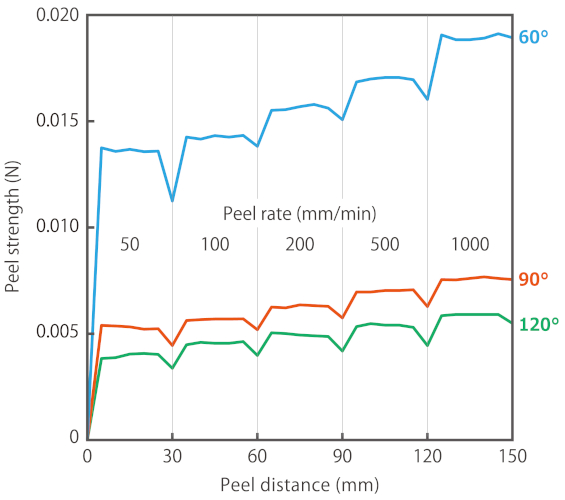

We measured using our Versatile Peel Analyzer model VPA-3, equipped with an optional full-scale 0.1N load cell. We examined the peel rate dependence on the peel angle by continuously changing the peel rate in one peel cycle. The peel angles were 60º, 90º, and 120º, and at each peel angle, the peel rates were 50mm, 100mm, 200mm, 500mm, and 1.000mm/min for every 30mm peel distance.

Figure 1 – Sample stage in different positions

Figure 2 – Comparison chart of the test results

Conclusion

The peel angle/rate dependence could be determined even though the peel force was as small as 0.005 to 0.02N. The most noticeable difference appeared at a peel angle of 60º.

Related Products

Visit our Virtual Showroom

to learn more about our company's products