Visual Impact Was Crucial

— Dr. Mari Koike of Nippon Dental University on Using Contact Angle Measurement for Evaluating Surface Properties of 3D-Printed Titanium

| 2025/11/18 | Mari Koike PhD: Nippon Dental University, College at Tokyo – Professor |

Dr. Mari Koike, Director of the Clinical Research Support Office, Nippon Dental University, and the interviewer from Kyowa Interface Science (from left).

In dentistry, titanium is gaining attention as a material with a low risk of metal allergies. In recent years, the development of 3D-printed titanium dental

materials has been progressing rapidly.

Dr. Mari Koike from the Clinical Research Support Office at Nippon Dental University, an expert in prosthodontics, is at the forefront of research exploring how

these titanium materials can be applied in dental treatments.

In this interview, we spoke with Dr. Koike about how our contact angle meter has been utilized to address one of the key challenges of 3D printing—surface

roughness—and to evaluate how well these materials integrate into the oral environment.

The Start of Research Focused on Titanium Safety

――― First, could you tell us about your specialty and what got you started with titanium

research?

Dr. Koike: My specialty is prosthodontics, which basically involves making dentures and dental

crowns. In general practice, we often use cobalt-chromium alloys or gold-silver-palladium alloys. However, a certain number of patients experience metal allergies with these materials. That’s

what led me to start using titanium as a safer alternative, and that’s how my research began.

Titanium is known as a safe material because it doesn’t easily corrode inside the body. But I wanted to understand how it behaves in the salty environment of

the mouth and explore ways to make it easier to use in dental applications. That’s been the focus of my research.

――― How has the technology for working with titanium evolved over time?

Titanium has a very high melting point around 1860℃, so initially it could only be processed with special casting machines. Later, digital methods emerged,

where shapes could be scanned and designed on a computer before manufacturing. Today, the third major method is 3D printing.

With 3D printing, layers of titanium powder are spread out and then fused with a laser or electron beam. Because the process is fully digital, it’s expected to

reduce the burden on patients and make treatments more efficient.

Challenges of Surface Roughness Unique to 3D Printing

――― Are there any challenges that are specific to 3D printing?

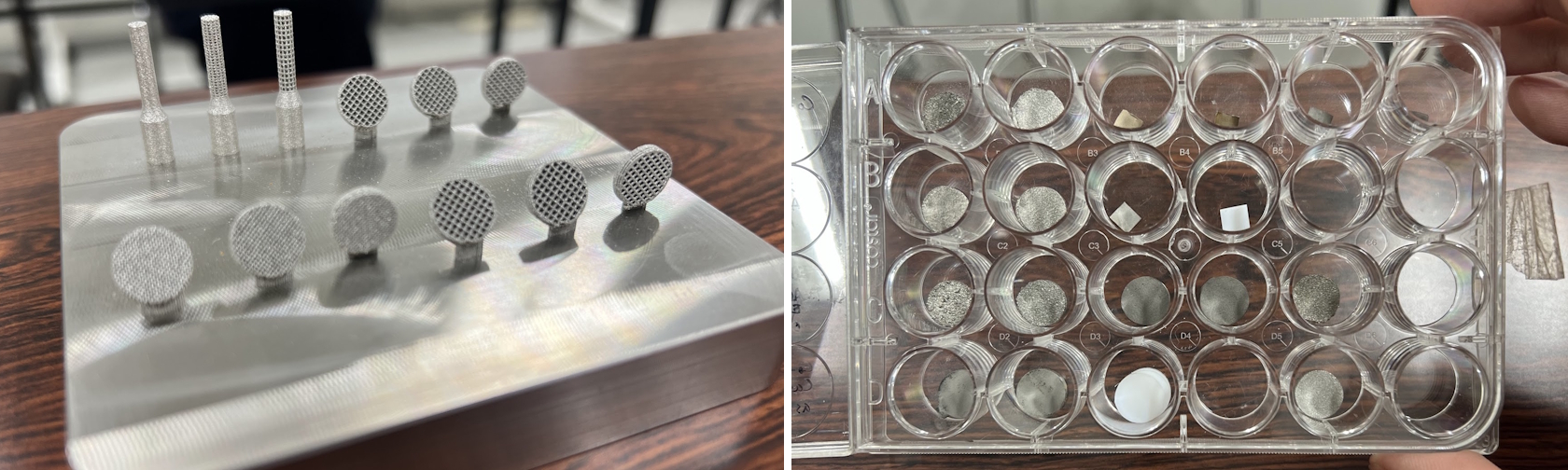

Yes. Because 3D printing builds objects from powder, the heat doesn’t always fully melt every particle, which can leave the surface uneven. For materials used

in the mouth, the surface needs to be smooth and resistant to buildup, like biofilm.

▲Samples and metal materials used to evaluate differences in surface properties depending on 3D printing method.

Another factor is the printing angle. The roughness of the surface can change depending on how the object is oriented during printing. For example, printing at

0 degrees (horizontally) versus 90 degrees (vertically) affects how the laser hits the powder, which in turn affects the surface finish.

So, it was crucial for us to carefully evaluate how the printing method and angle influence the surface characteristics of the final product.

Visual Impact Changed the Direction of the Research

――― So that’s when evaluating surface characteristics became necessary?

Exactly. Alongside properties like strength and corrosion resistance, I had always wanted to investigate the “surface tension,” or wettability, of the material.

I remember seeing presentations at conferences where they dropped a liquid droplet on a surface and showed how it spread, and I thought that was fascinating. But at the time, I didn’t know who I could consult about actually measuring it.

By chance, I met the sales representative from Kyowa Interface Science at an exhibition. He suggested, ‘Why don’t we try measuring it?’ I left him some

samples, and that became the start of our ongoing collaboration.

――― What significance did the contact angle measurements have for your research?

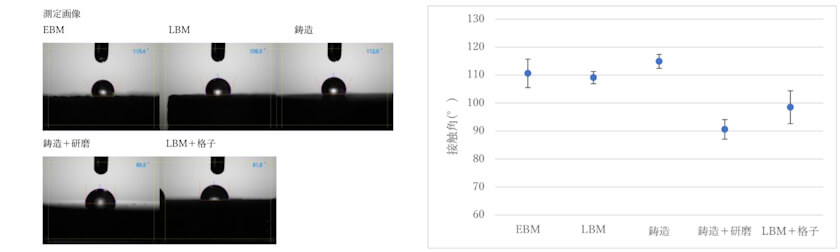

As we progressed, I already knew that the surface roughness varied depending on the printing angle. But when presenting this in papers, just stating numbers

like “the roughness differs” didn’t really convey the difference to readers.

When I saw the droplet images provided by the team, it was immediately clear visually: “Yes, these two surfaces are definitely different.” The visual impact was huge.

――― So both numerical data and visual information were important.

Absolutely. Just saying “the contact angle is X degrees” doesn’t really give a clear image. But if you show a photo where a water droplet is perfectly round versus one where it spreads flat, you can intuitively understand what the numbers mean. As the saying goes, “seeing is believing,” and being able to visualize it is

extremely important.

What impressed me most about the team was Kyowa’s thoroughness. Unlike other measurement services that often provide results from a single measurement, Kyowa conducted enough repeated measurements to ensure reproducibility. Kyowa carefully checked for variations in the data and provided very meticulous

support.

Thanks to Kyowa’s efforts, we were able to express the surface roughness both visually and numerically in my papers, achieving exactly what I wanted with the materials. Although the droplet photos couldn’t be included in conference posters due to space limitations, the visual information we obtained through these

measurements had a significant impact on understanding our research.

▲Excerpt from the evaluation report prepared for Dr. Koike on differences in surface properties by build method (partial extract).

Establishing Standards for Use in the Oral Cavity

――― How are the measurement results being used?

Measuring the contact angle is extremely important as one of the ways to evaluate material properties, just like we did in the paper we published.

From this research, we gained insight such as, “With this level of roughness and this kind of surface condition, the contact angle will generally be around this

value.” This knowledge serves as a useful standard for determining whether 3D-printed titanium can actually be used safely and effectively in the oral cavity.

Aiming for Strong Collaboration Between Researchers and Companies

――― As the director of the Clinical Research Support Office, you also support other

researchers, right?

Yes. Alongside my own research, I help others who may not be familiar with statistics, and I

assist in building “connections” with external companies or experts, similar to what I’ve done

myself.

Since graduating, I haven’t had many opportunities to learn new things, so I often attend

seminars to keep my knowledge up to date. When webinars started during the COVID-19

pandemic, it was especially useful because I could participate without spending time traveling.

――― What do you think about our webinars and other information sharing?

“Collaboration between companies and researchers is really important.”

In that regard, I think your seminars at Kyowa Interface Science are excellent. Often, seminars from other companies end with a pitch like, “You can only do this with our equipment,” but your seminars rarely do that.

As a researcher, I want to hear a balanced mix of basic concepts and specialized applications. Continuing to share a variety of information—including cases like mine—can give other researchers hints and ideas, like, “Oh, this is one way to do it.”

I also hope to act as a hub myself, so that when someone is struggling, I can say, “Here’s a method you could try.” I look forward to continuing good collaboration in the future.

Related Paper

Below is the abstract of the paper describing the present study, for which Dr. Koike served as the first author.

Surface Morphologies on an Additive-Manufactured Titanium Alloy for Biofilm Formation

(2024 IADR/AADOCR/CADR General Session)

[Instruments Used] Contact Angle Meter DMs-402

This instrument enables automatic droplet recognition at the moment of image capture in the image-processing function for contact angle

measurement. By automating the step that is most susceptible to individual operator judgment, the device reduces measurement variability caused

by personal error.